2025.05.09

2025.05.09

Industry News

Industry News

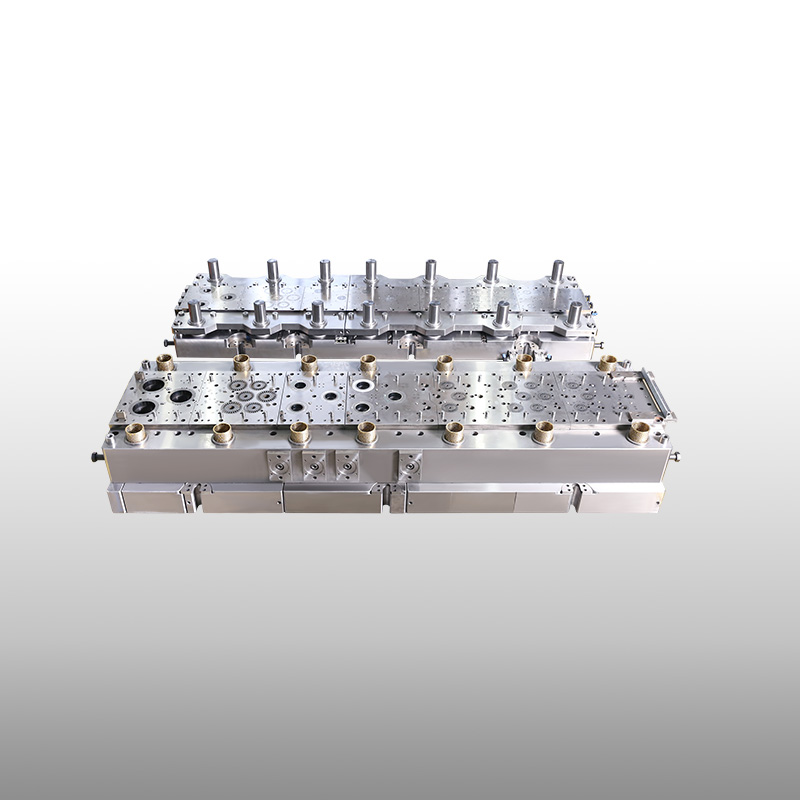

In the relentless pursuit of industrial efficiency, the high speed stamping mold has emerged as a cornerstone of modern manufacturing. These precision tools, integral to the automotive and electronics sectors, are designed to produce parts with unmatched speed and precision. This article delves into the dynamic balance technology that has revolutionized the high speed stamping mold industry, ensuring both rapid production and steadfast reliability.

The high speed stamping mold is not just a tool; it's a testament to engineering prowess. Its ability to stamp out parts at breakneck speeds has been a game-changer for industries demanding high-volume production. However, the real challenge lies in maintaining precision and durability while operating at such high speeds. This is where the dynamic balance of high speed stamping molds comes into play.

The dynamic balance technology in high speed stamping molds is akin to the equilibrium one finds in a well-oiled machine. It involves a complex interplay of design, materials, and manufacturing processes that together ensure the mold's longevity and performance. By fine-tuning these elements, manufacturers can achieve a harmonious blend of speed and stability in their high speed stamping molds.

One of the key aspects of high speed stamping mold balance is the selection of materials. High-grade steels and advanced alloys are often chosen for their strength and resistance to wear. These materials can withstand the relentless forces exerted during the stamping process, ensuring that the mold maintains its shape and accuracy over time. The use of such materials in high speed stamping molds is crucial for maintaining the integrity of the parts produced.

The design of high speed stamping molds also plays a significant role in their dynamic balance. Engineers must consider the distribution of forces and the flow of materials during the stamping process. This involves intricate calculations and simulations to ensure that the mold can handle the stresses of high-speed operations without compromising the quality of the final product. The design of high speed stamping molds is a delicate balance of art and science, where every detail counts.

Manufacturing processes are another critical factor in achieving dynamic balance in high speed stamping molds. Advanced techniques such as computer-aided design (CAD) and computer-aided manufacturing (CAM) are employed to create molds with high precision. These technologies allow for the production of molds that are not only fast but also consistent in their output. The manufacturing processes for high speed stamping molds are continuously evolving, with new methods being developed to push the boundaries of what's possible.

Maintenance and upkeep are equally important for the dynamic balance of high speed stamping molds. Regular inspections and adjustments help to identify and rectify any imbalances that may occur over time. This proactive approach to maintenance is essential for ensuring that the mold continues to perform at its best, even as it endures the rigors of high-speed stamping.

As technology advances, the dynamic balance technology in high speed stamping molds is becoming more sophisticated. Innovations such as predictive maintenance, which uses data analytics to forecast potential issues before they occur, are being integrated into the management of these molds. This not only enhances the performance of high speed stamping molds but also contributes to the overall efficiency of the production process.

In conclusion, the dynamic balance technology in high speed stamping molds is a critical component of modern manufacturing. It enables the production of high-quality parts at remarkable speeds while ensuring the longevity and reliability of the mold itself. As industries continue to push the limits of what's possible, the high speed stamping mold remains at the forefront, a symbol of the dynamic balance between speed and stability.