2025.05.30

2025.05.30

Industry News

Industry News

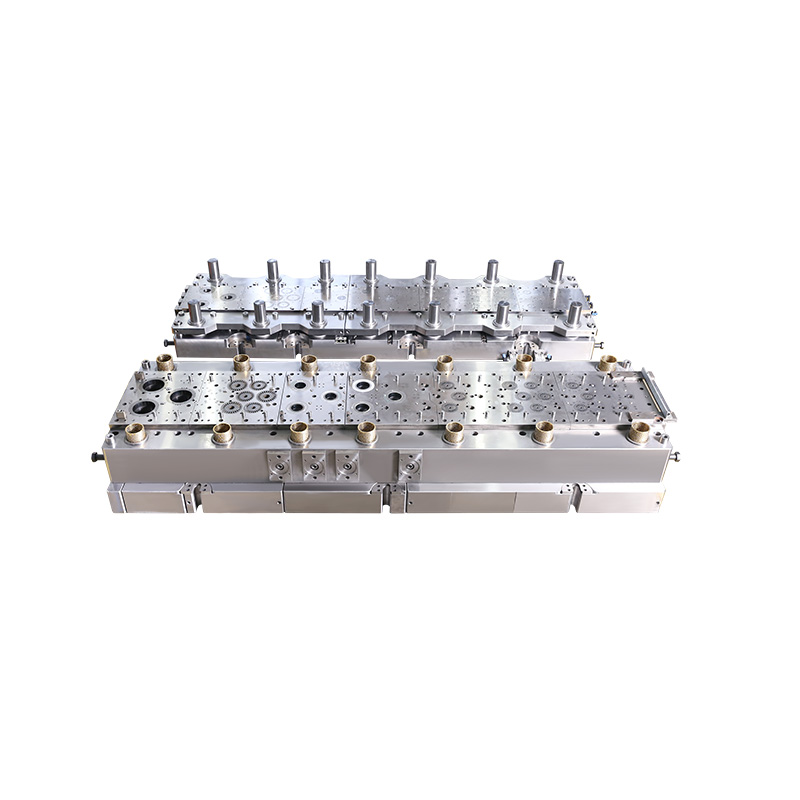

In the realm of manufacturing, the progressive stamping mold has been a cornerstone technology for producing intricate and precise parts with exceptional efficiency. This article delves into the application of progressive stamping molds in the creation of electronic hardware components, such as terminals, spring blades, and conductive plates, highlighting their importance in the electronics industry.

The progressive stamping mold, a highly specialized tool used in metal stamping, has revolutionized the production of electronic hardware components. These components are essential in various electronic devices, ensuring connectivity, flexibility, and conductivity. The process involves a series of sequential operations that transform a flat sheet of metal into a finished part in a single stroke of the press, which is why progressive stamping molds are favored for their efficiency and precision.

Electronic hardware components, such as terminals and spring blades, require high precision and consistency to ensure reliable performance. Progressive stamping molds excel in this regard, offering tight tolerances and repeatability. The design of these molds allows for multiple stations to be integrated into a single die, which means that the metal is progressively shaped through each station, resulting in a complex part that meets the stringent specifications required for electronic applications.

One of the key advantages of progressive stamping molds in the production of electronic hardware components is the reduction of waste material. Traditional stamping processes often result in significant material loss, but with progressive stamping molds, the material utilization rate is significantly higher. This not only lowers production costs but also aligns with the industry's move towards sustainability and waste reduction.

Conductive plates, integral to the electronic industry for their role in ensuring electrical connectivity, are another area where progressive stamping molds shine. These components must maintain conductivity while withstanding harsh environmental conditions. Progressive stamping molds are capable of producing conductive plates with uniform thickness and surface finish, crucial for maintaining consistent electrical performance.

The versatility of progressive stamping molds is evident in their ability to produce a wide range of electronic hardware components, from simple terminals to complex multi-layered structures. This adaptability is crucial as electronic devices become more compact and sophisticated, requiring components that can meet these evolving demands.

In the competitive landscape of electronic manufacturing, the use of progressive stamping molds offers a competitive edge. By streamlining the production process and reducing the number of steps required to produce electronic hardware components, manufacturers can decrease time and increase output. This efficiency is particularly valuable in high-demand markets where rapid product turnover is the norm.

Quality control is a critical aspect of electronic hardware component production, and progressive stamping molds contribute significantly to this. The ability to closely monitor and adjust the stamping process in real-time ensures that each component produced is consistent and meets the required specifications. This level of control is essential for maintaining the reliability and performance of electronic devices.

As the electronic industry continues to grow, the demand for advanced and reliable progressive stamping molds is set to increase. Manufacturers are constantly seeking ways to improve their processes, and progressive stamping molds offer a solution that combines efficiency, precision, and quality. The integration of these molds into the production line is likely to be a key factor in the success of electronic hardware component manufacturers.

In conclusion, progressive stamping molds play a pivotal role in the production of electronic hardware components such as terminals, spring blades, and conductive plates. Their ability to produce high-quality, precise parts with minimal waste and efficiency makes them an invaluable tool in the electronics manufacturing sector. As technology advances and the demand for complex electronic components grows, the progressive stamping mold will continue to be a central component in meeting these challenges.