2025.09.08

2025.09.08

Industry News

Industry News

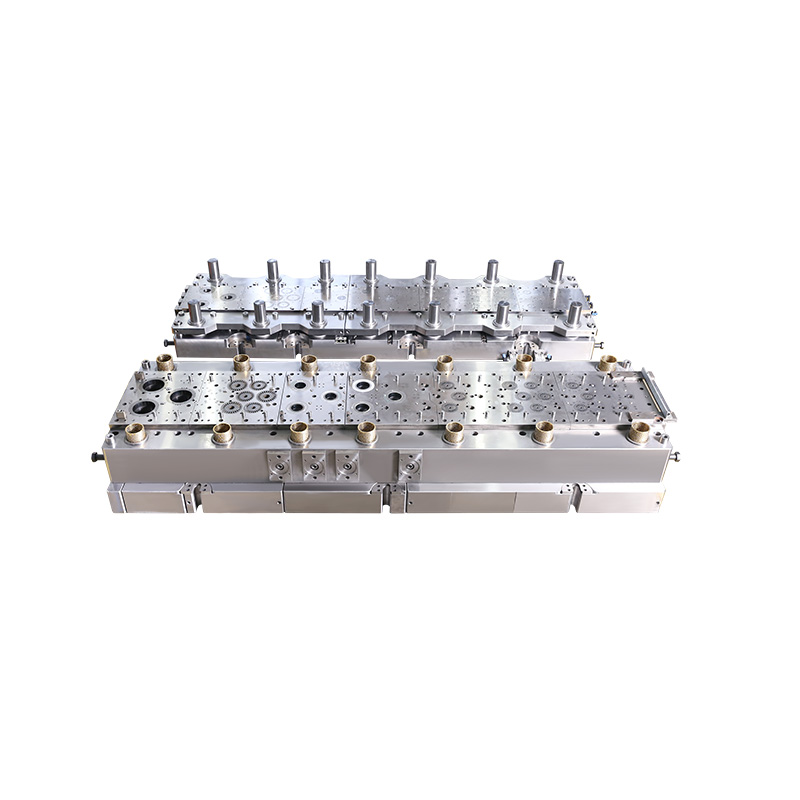

In today’s competitive manufacturing environment, the High Speed Stamping Mold plays a key role in enabling efficient and precise production. As industries demand greater accuracy, durability, and productivity, the focus has shifted to the materials and manufacturing processes behind these molds. Recent developments in steel selection, heat treatment, and machining technologies are providing manufacturers with new opportunities to improve both performance and cost efficiency.

Material Selection for High Speed Stamping Mold

The choice of materials has a direct impact on the durability and stability of a High Speed Stamping Mold. High-speed steel remains a popular option due to its balance of toughness and wear resistance, making it suitable for demanding stamping conditions. Carbide materials, known for their hardness, are particularly effective in applications that require long service life and high-volume production. Powder metallurgy steels have also gained attention because they combine fine microstructures with enhanced strength, offering mold makers greater flexibility in design. By carefully selecting between high-speed steel, carbide, and powder metallurgy materials, manufacturers can match the mold’s properties to the specific requirements of the stamping process.

Heat Treatment and Surface Treatment

Another area of progress is heat treatment and surface engineering. A High Speed Stamping Mold must withstand repeated impacts, which can to wear and fatigue over time. Heat treatment techniques such as vacuum hardening and tempering are widely used to improve hardness and toughness. Surface treatments, including nitriding, PVD coatings, and specialized surface polishing, are applied to further enhance wear resistance and reduce friction. These processes extend the mold’s service life and minimize downtime caused by maintenance or replacement. In industries where production runs are long and quality standards are strict, such improvements make a measurable difference in efficiency.

Manufacturing Processes

The production of a High Speed Stamping Mold also depends heavily on advanced machining technologies. CNC machining ensures dimensional accuracy and repeatability, which are essential for molds that must operate at high speeds without deviation. Electrical Discharge Machining (EDM) allows for complex geometries and fine details that are difficult to achieve with traditional methods. In addition, high-precision EDM and wire-cutting processes contribute to producing molds with tight tolerances, ensuring consistent stamping results. These manufacturing methods not only improve the quality of the mold itself but also support faster times and reduced development costs.

Industry Applications and Value

With advances in materials and processing, the High Speed Stamping Mold has become more reliable and versatile. In electronics, it enables precise production of small components with strict dimensional requirements. In the automotive sector, it supports mass production of complex metal parts, ensuring consistency and safety. The household appliance industry also benefits from molds that can handle repeated cycles without performance loss. As manufacturers continue to adopt more durable materials, improved heat treatments, and precision machining, the performance of the High Speed Stamping Mold is expected to grow in line with rising global demand.

The latest developments in steel selection, heat and surface treatments, and machining technologies are reshaping the capabilities of the High Speed Stamping Mold. By combining the strengths of materials like high-speed steel, carbide, and powder metallurgy with advanced processing methods such as CNC and EDM, manufacturers are building molds that deliver greater wear resistance, stability, and efficiency. These improvements not only extend mold life but also provide industries with consistent and cost-effective production tools. As innovation continues, the High Speed Stamping Mold will remain central to achieving high-quality output in modern manufacturing.