2025.08.29

2025.08.29

Industry News

Industry News

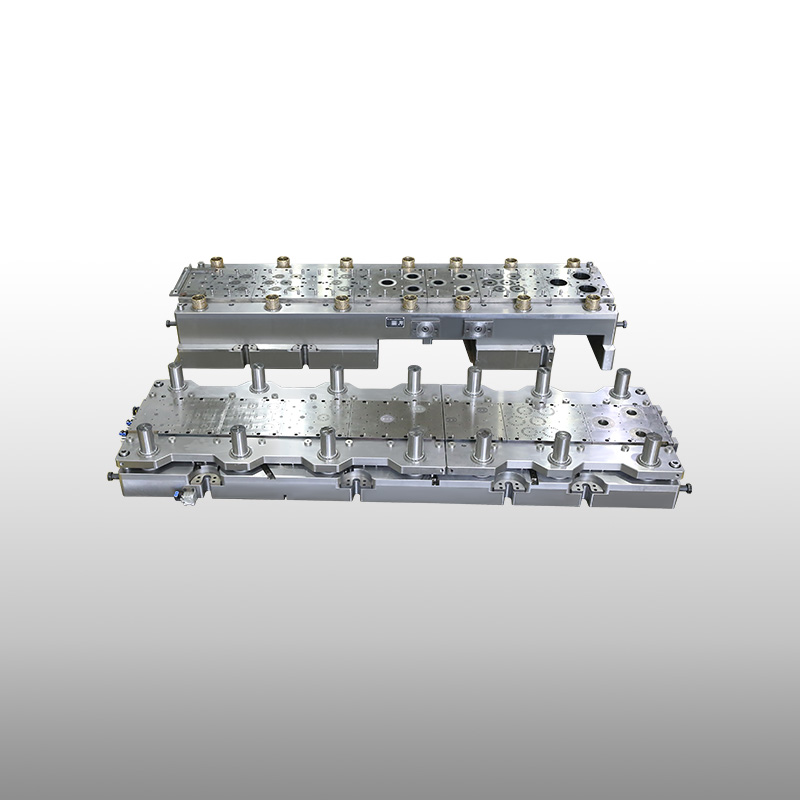

As production demands rise and tolerance requirements become tighter, selecting the right mold steel and employing effective surface enhancements are critical to ensure consistent quality and operational efficiency. Understanding how these factors influence the durability and wear resistance of a High Speed Progressive Stamping Die can provide manufacturers with the competitive edge necessary for sustained success.

Selecting the Mold Steel for High Speed Progressive Stamping Die

The core of any reliable High Speed Progressive Stamping Die lies in the steel used for its construction. Mold steels must combine hardness, toughness, and fatigue resistance to withstand the intense and rapid mechanical stresses characteristic of high-speed stamping operations. Commonly used materials include D2, A2, and S7 tool steels, each offering a balance of wear resistance and impact strength.

D2 steel, known for its high carbon and chromium content, provides hardness and abrasion resistance, making it a popular choice for cutting and blanking components of a Speed Progressive Stamping Die. However, it is somewhat less tough compared to other steels, so it is often paired with strategic design to minimize shock impact.

A2 tool steel presents a good compromise between hardness and toughness, making it suitable for parts of the High Speed Progressive Stamping Die exposed to varied stresses. Its air-hardening property allows for easier heat treatment, optimizing performance without compromising structural integrity.

S7 steel is favored where impact resistance is paramount. For components in a High Speed Progressive Stamping Die that endure sudden loads or shocks, S7 reduces the risk of cracking or premature failure, albeit with slightly lower wear resistance than D2.

The Role of Surface Treatment in Extending Die Life

Beyond base material selection, surface treatments significantly enhance the wear resistance and lifespan of a High Speed Progressive Stamping Die. Techniques such as nitriding, PVD (Physical Vapor Deposition) coatings, and laser hardening modify the die’s surface to resist abrasion, corrosion, and fatigue.

Nitriding introduces nitrogen into the steel surface, creating a hard, wear-resistant layer without affecting the die’s core toughness. This treatment is particularly beneficial for High Speed Progressive Stamping Die components that face constant friction, such as guide pins and punch faces.

PVD coatings, including titanium nitride (TiN) and chromium nitride (CrN), deposit a thin, durable layer on the die surface. These coatings reduce friction and prevent galling, which is essential for maintaining the precision and smooth operation of a High Speed Progressive Stamping Die over long production runs.

Laser hardening, which uses concentrated laser beams to selectively harden specific areas, allows for tailored surface properties on a High Speed Progressive Stamping Die. This process preserves the die’s overall toughness while providing exceptional wear resistance where needed most.

Improving Wear Resistance and Fatigue Strength

The combination of proper material selection and advanced surface treatments lays the foundation for improved wear resistance and fatigue strength in a High Speed Progressive Stamping Die. However, additional strategies can further extend die life.

Precision manufacturing processes, including tight machining tolerances and stress-relief heat treatments, reduce internal stresses that contribute to fatigue. Design considerations such as uniform load distribution and minimizing stress concentrations also play a crucial role.

Regular maintenance and timely refurbishment ensure that the High Speed Progressive Stamping Die operates within parameters. Re-polishing wear areas, replacing inserts, and reapplying surface coatings as needed prevent premature deterioration and production downtime.

In conclusion, the durability and performance of a High Speed Progressive Stamping Die heavily depend on the careful selection of mold steel and the application of innovative surface treatments. Choosing the right steel grade to balance hardness and toughness, combined with targeted surface enhancements, significantly improves wear resistance and fatigue life. By adopting these materials and treatment strategies, manufacturers can ensure their High Speed Progressive Stamping Die delivers reliable, high-quality stamping results over extended production cycles, ultimately enhancing productivity and cost-effectiveness.