2025.08.15

2025.08.15

Industry News

Industry News

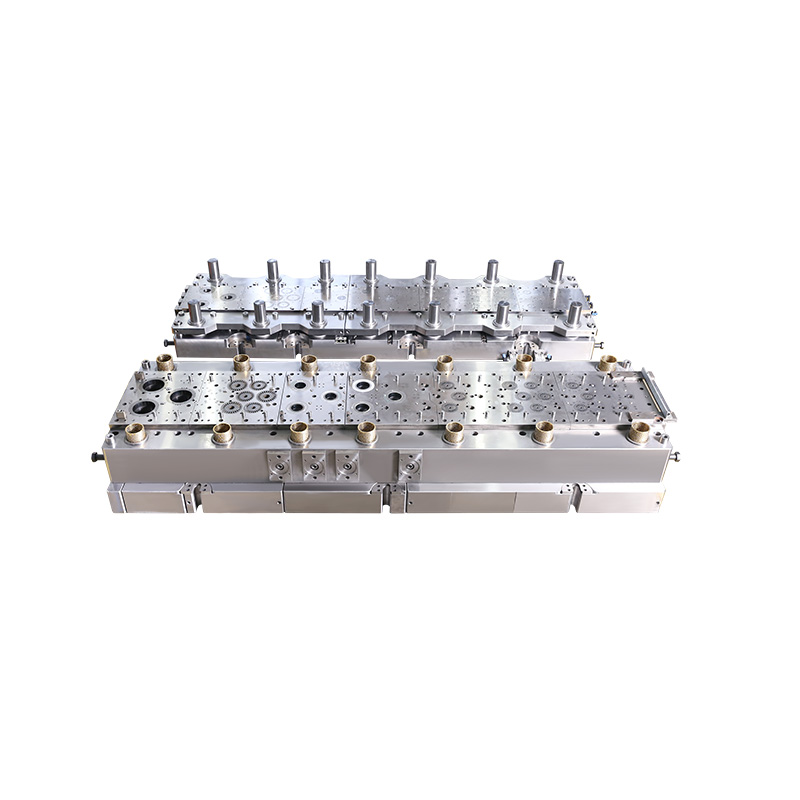

In today’s competitive manufacturing landscape, Mold Customization plays an essential role in delivering precision parts tailored to specific product requirements. However, the value of customized molds extends far beyond their initial production. Effective after-sales service, proactive maintenance, and timely repair are crucial components that ensure molds continue to perform reliably throughout their lifecycle. Understanding how to maintain and extend the lifespan of molds created through Mold Customization is vital for manufacturers seeking to maximize return on investment and maintain production efficiency.

Maintenance Methods for Customized Molds

Proper maintenance is the foundation of mold longevity following Mold Customization. Regular cleaning is among the simplest yet important tasks. Residual materials, lubricants, and contaminants must be thoroughly removed after each production run to prevent corrosion or surface damage. Using appropriate solvents and soft brushes helps preserve the mold’s surface integrity without causing abrasion.

Lubrication is another key factor in mold care. Customized molds often include moving parts such as slides, lifters, and ejector pins. These components require consistent lubrication to reduce friction and wear. Applying the right type of lubricant, as recommended by mold manufacturers, ensures smooth operation and prevents premature failure.

Routine inspection is essential in identifying early signs of wear or damage. During scheduled maintenance, technicians should examine critical areas such as cavities, cores, and parting lines for cracks, deformation, or erosion. Early detection enables swift corrective measures, reducing downtime and preventing costly production interruptions.

Repair and Improvement Services for Customized Molds

Despite careful maintenance, molds from Mold Customization inevitably experience wear and tear due to high operational demands. Timely repair services are therefore indispensable. Repair work often involves re-polishing worn surfaces, replacing damaged inserts, or welding and machining areas affected by cracks or corrosion.

Advanced repair techniques, including laser welding and precision machining, allow customized molds to regain their original accuracy and finish. These methods help restore molds without the need for costly complete replacements, thereby offering economic benefits.

In addition to repair, improvement services are an important part of the after-sales support for Mold Customization. As production requirements evolve, molds can be modified to enhance performance or adapt to new materials. Such improvements may include redesigning cooling channels for better temperature control or altering venting systems to reduce cycle times. Working closely with mold manufacturers to implement these upgrades can significantly improve product quality and manufacturing efficiency.

Tips to Extend the Lifespan of Customized Molds

Extending the life of molds produced via Mold Customization begins with proper handling and storage. Molds should be stored in a clean, dry environment with protective coatings applied to prevent rust. Avoiding impacts or mishandling during transportation and installation minimizes the risk of physical damage.

Implementing a strict maintenance schedule is another effective way to prolong mold service life. Maintenance intervals should be based on production volume and material abrasiveness, ensuring that molds are serviced before wear adversely affects product quality.

Training machine operators and maintenance personnel is equally important. Educated staff can recognize early signs of mold issues and follow practices in mold operation, reducing the risk of accidental damage.

Lastly, maintaining clear records of maintenance, repairs, and modifications related to Mold Customization molds facilitates informed decision-making. Tracking mold history helps identify recurring problems and plan preventive strategies, ensuring molds remain productive for longer periods.

The success of Mold Customization does not end once the mold is manufactured and delivered. Comprehensive after-sales service, including regular maintenance, prompt repair, and strategic improvements, is essential to maximize mold lifespan and maintain manufacturing quality. By adopting these practices, manufacturers can protect their investment in customized molds, reduce downtime, and consistently produce high-quality components that meet evolving market demands.