2025.09.19

2025.09.19

Industry News

Industry News

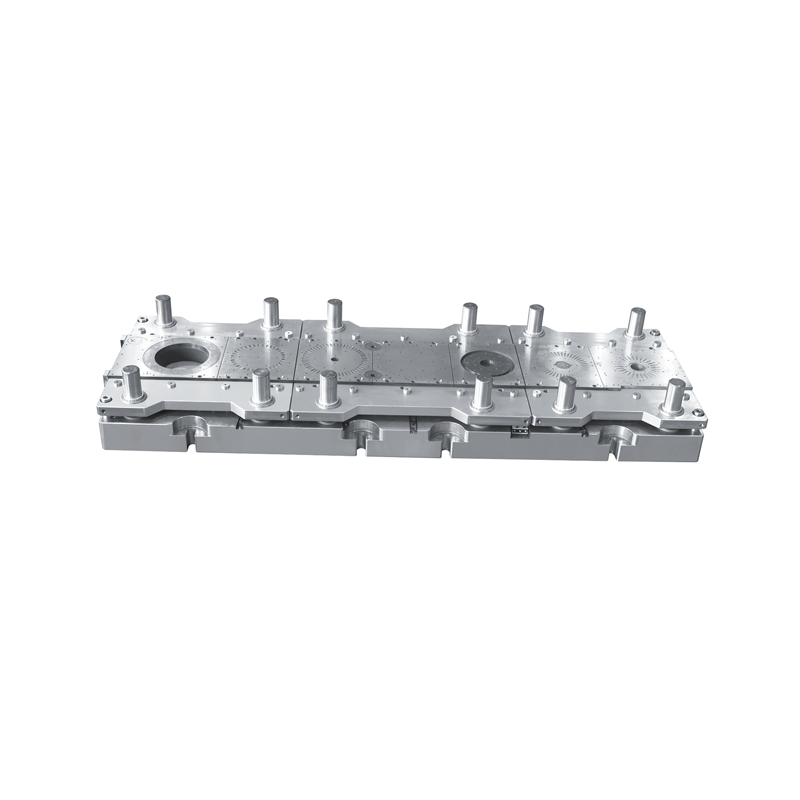

In modern manufacturing, stamping molds play a central role in shaping metal parts with precision. Among the different types, the High Speed Stamping Mold has become increasingly important, especially in industries where efficiency and accuracy are critical. While conventional molds are still widely used, there are notable differences between them and the High Speed Stamping Mold that influence production outcomes, cost efficiency, and quality.

Definition and Working Principle

A conventional stamping mold is designed to operate at moderate speeds, suitable for producing general parts with acceptable accuracy. In contrast, a High Speed Stamping Mold is engineered to work with high-speed presses, often running at hundreds of strokes per minute. This allows manufacturers to produce large volumes of components in a shorter time, making it suitable for industries such as electronics, automotive, and energy.

Production Efficiency

The obvious distinction lies in productivity. A High Speed Stamping Mold enables continuous, fast-paced operations without compromising dimensional stability. For manufacturers dealing with mass production, such as electrical motor cores or precision connectors, this feature translates into reduced cycle times and increased throughput. Conventional molds, while reliable, cannot match the same level of speed and efficiency, making them more appropriate for smaller production runs or less complex parts.

Accuracy and Consistency

Another major difference is in precision. The High Speed Stamping Mold is built with advanced guiding systems, specialized tool steels, and precise alignment features. This ensures that each stroke delivers consistent results, reducing variation in the final product. Conventional molds, though effective for general purposes, may show greater wear over time and produce less uniform results when operating at higher speeds.

Material Utilization

Material efficiency is another factor where the High Speed Stamping Mold shows advantages. Through optimized strip layouts and progressive die designs, it reduces scrap and maximizes the use of raw material. Conventional molds may not achieve the same level of optimization, which can to higher material consumption and cost in large-scale production.

Tool Life and Maintenance

The durability of the High Speed Stamping Mold also sets it apart. With advanced coatings, heat treatment, and specialized alloys, these molds are designed to withstand the stress of high-frequency operations. Although maintenance is still required, the overall tool life is generally longer compared to conventional molds used under similar workloads. On the other hand, standard molds may require more frequent adjustments and replacements when pushed beyond their intended capacity.

Applications and Industry Relevance

The High Speed Stamping Mold is commonly used in industries where precision and high volume are essential. Examples include electric motor laminations, transformer parts, battery components, and electronic connectors. Conventional molds remain relevant for industries that do not demand extremely high speeds, such as household appliance parts or general sheet metal fabrication.

The choice between a conventional stamping mold and a High Speed Stamping Mold depends on the production requirements of a project. When high output, precision, and material efficiency are priorities, the High Speed Stamping Mold offers significant advantages. Conventional molds, however, still serve as practical solutions for lower-volume or less demanding tasks. By understanding the differences between the two, manufacturers can select the right tool to balance cost, efficiency, and quality in their operations.