2025.09.25

2025.09.25

Industry News

Industry News

In the field of metal forming, selecting the right mold is essential to ensure efficient production, consistent quality, and cost-effectiveness. Among the widely used options are the Progressive Stamping Mold and the transfer mold. Both methods serve the purpose of shaping and producing metal parts, but they differ in design, operation, and applications. Understanding these differences helps manufacturers decide which option suits their production needs .

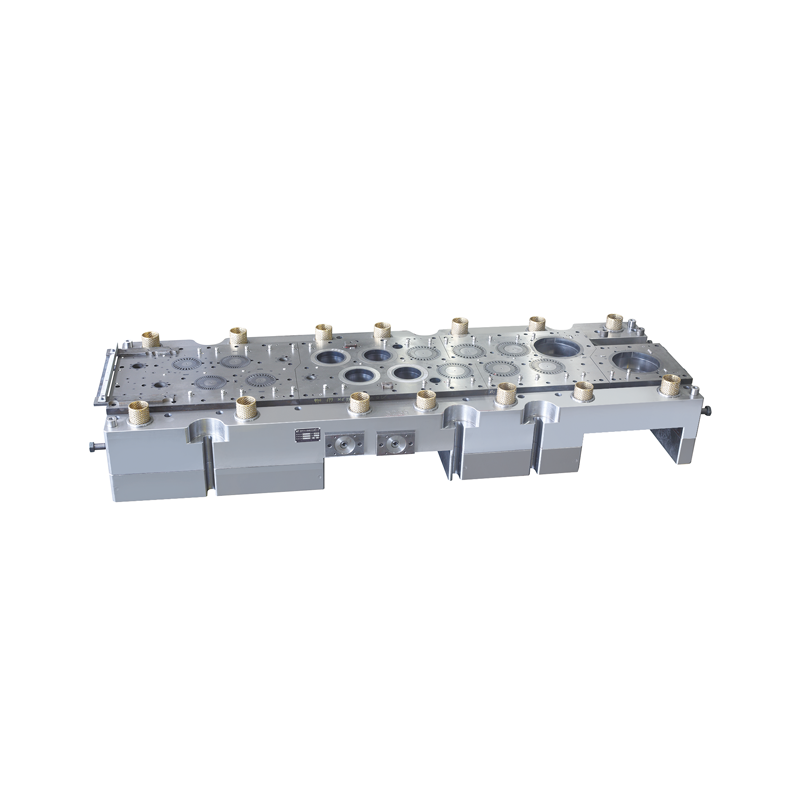

What Is a Progressive Stamping Mold?

A Progressive Stamping Mold is designed to perform multiple operations on a strip of metal as it advances through a press. Each station in the mold completes a different step, such as punching, bending, or forming. By the time the strip reaches the final stage, a finished part is separated from the material.

The main advantage of a Progressive Stamping Mold is its efficiency. It allows manufacturers to produce large volumes of small- to medium-sized components with consistent quality. Additionally, material utilization is typically higher because the process is optimized to reduce waste.

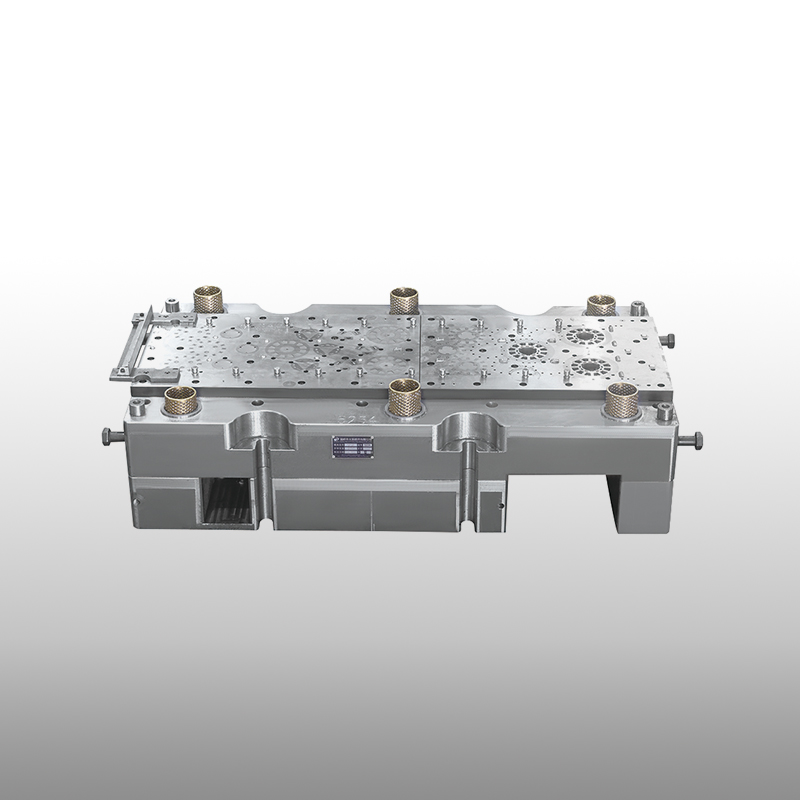

What Is a Transfer Mold?

A transfer mold, on the other hand, works by moving individual pieces of metal from one station to another. At each station, a different operation is performed, but instead of being carried along a strip, the part is transferred mechanically or with a robotic system.

This method offers flexibility in handling larger or more complex parts that may not be suitable for a Progressive Stamping Mold. Since each piece is worked on individually, transfer molds can manage parts that require deep drawing or multiple forming steps.

Key Differences Between Progressive Stamping Mold and Transfer Mold

Material Handling

Progressive Stamping Mold: Operates with continuous strip feeding, making it ideal for small, repeatable components.

Transfer Mold: Handles separate blanks, allowing more flexibility in part size and shape.

Production Efficiency

Progressive Stamping Mold: suited for high-volume production, offering speed and reduced labor involvement.

Transfer Mold: Slower in comparison but better for producing larger or irregular parts.

Part Complexity

Progressive Stamping Mold: Designed for parts that can be completed through sequential operations in a strip.

Transfer Mold: Better for components with complex shapes, deep drawing, or multiple bends that require individual handling.

Tooling Costs

Progressive Stamping Mold: Often requires higher initial investment but results in lower cost per part for large production runs.

Transfer Mold: Generally more affordable upfront but may to higher per-part costs in mass production.

Applications

Progressive Stamping Mold: Automotive terminals, electrical connectors, brackets, and consumer goods.

Transfer Mold: Large automotive body parts, deep-drawn cups, and structural components.

When to Choose a Progressive Stamping Mold?

A Progressive Stamping Mold is ideal when:

You need high-volume production.

Parts are relatively small and can be formed from a strip.

Consistency and reduced waste are priorities.

Automation and minimal operator involvement are desired.

This makes the Progressive Stamping Mold especially valuable in industries such as automotive, electronics, and consumer goods manufacturing.

When to Choose a Transfer Mold?

A transfer mold is the better option when:

The parts are larger or too complex for a strip-fed process.

Deep drawing or multiple shaping steps are necessary.

Flexibility in part design is more important than speed.

Production runs are medium volume rather than extremely high.

Transfer molds are widely used in heavy industries and for components that require additional forming depth or strength.

Both the Progressive Stamping Mold and the transfer mold are effective tools for metal forming, but their suitability depends on the type of part being produced, production volume, and cost considerations. A Progressive Stamping Mold offers efficiency, high output, and material utilization, making it the preferred choice for mass production of small to medium-sized parts. In contrast, transfer molds provide flexibility and are better suited for larger, complex components.

By carefully evaluating the nature of your projects, you can determine whether a Progressive Stamping Mold or a transfer mold will deliver the balance of productivity, cost, and quality for your manufacturing process.