2025.10.03

2025.10.03

Industry News

Industry News

In the realm of modern electronics, precision and efficiency are paramount. High speed stamping mold has emerged as a crucial technology that significantly enhances the production process of various electronic components, particularly in the manufacturing of motor laminations, electric motor stampings, and connectors. This article delves into the importance and applications of high speed stamping mold in these areas.

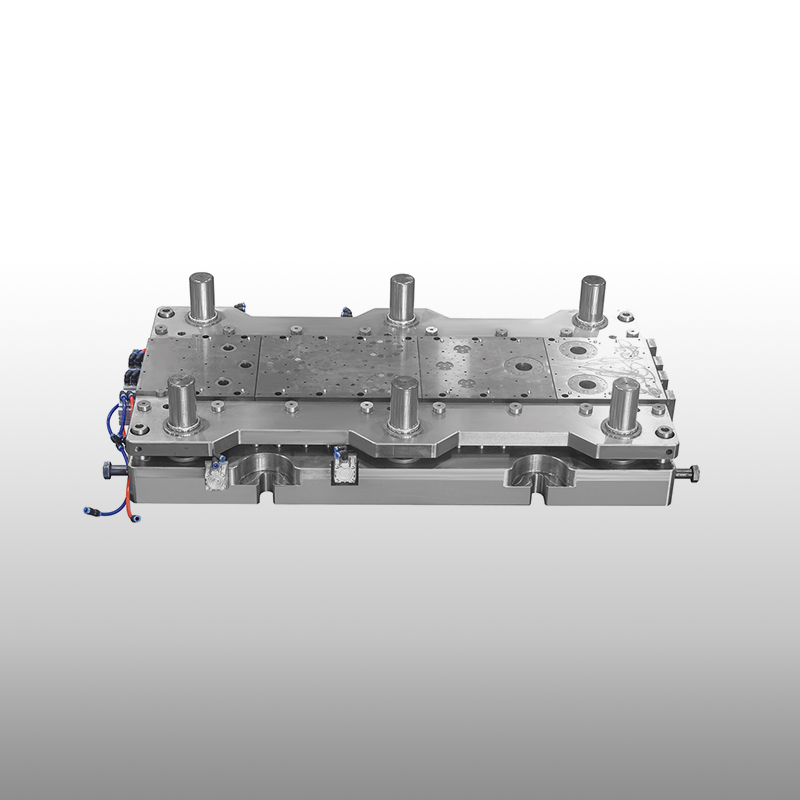

High speed stamping mold is a sophisticated manufacturing technology that allows for the rapid and precise production of metal components. It involves the use of powerful presses and intricately designed molds to shape metal blanks into the desired forms. The process is characterized by its high production rate and exceptional accuracy, making it ideal for mass production of electronic components.

In the production of motor laminations, high speed stamping mold plays a pivotal role. Motor laminations are thin sheets of metal that are stacked together to form the core of an electric motor. The precision of the stamping process ensures that each lamination is identical in size and shape, which is critical for the efficient functioning of the motor. High speed stamping mold allows manufacturers to produce thousands of laminations per hour, significantly reducing production time and costs. Moreover, the high precision of the molds ensures that the laminations fit together perfectly, minimizing energy losses and the motor’s efficiency.

Similarly, in the manufacturing of electric motor stampings, high speed stamping mold is indispensable. These stampings are used to create various parts of the motor, such as the rotor and stator. The complex shapes and tight tolerances required for these components can be achieved through the use of high speed stamping molds. The molds are designed with great precision to ensure that each stamping is produced to exact specifications. This not only improves the performance of the motor but also enhances its reliability and durability. High speed stamping mold technology enables manufacturers to produce high-quality motor stampings at a fraction of the time and cost compared to traditional manufacturing methods.

High speed stamping mold is also widely used in the production of electronic connectors. Connectors are essential components in electronic devices, providing the means for electrical connections between different parts of the device. The precision and consistency of high speed stamping mold are crucial in ensuring that connectors meet the stringent requirements of modern electronics. The molds are designed to produce connectors with precise dimensions and high-quality finishes, which are essential for reliable electrical connections. High speed stamping mold allows manufacturers to produce large quantities of connectors quickly and efficiently, meeting the growing demand for electronic devices.

The benefits of high speed stamping mold extend beyond just the production of individual components. It also has a significant impact on the overall manufacturing process. The high production rate of high speed stamping mold reduces the time required for each production cycle, to shorter times and faster delivery of products. This is particularly important in the fast-paced electronics industry, where time-to-market is a critical factor. Additionally, the precision of high speed stamping mold reduces the need for secondary operations, such as machining or grinding, further reducing production costs and improving efficiency.

High speed stamping mold is a vital technology in the manufacturing of electronic products. Its ability to produce high-quality components quickly and efficiently has revolutionized the production of motor laminations, electric motor stampings, and connectors. The precision and consistency of high speed stamping mold ensure that these components meet the stringent requirements of modern electronics, contributing to the overall performance and reliability of electronic devices. As the electronics industry continues to evolve, high speed stamping mold will undoubtedly remain a key technology, driving innovation and efficiency in the manufacturing process.