2025.10.10

2025.10.10

Industry News

Industry News

If you're involved in manufacturing, especially in sectors like automotive, aerospace, or consumer goods, you've likely faced challenges in finding efficient and durable tooling solutions that can keep up with production demands while maintaining precision. One of the effective answers to these challenges lies in using a well-designed Stamping Mold. But what makes this tooling option worth considering, and how can partnering with an experienced Stamping Mold Manufacturer make a tangible difference in your operations?

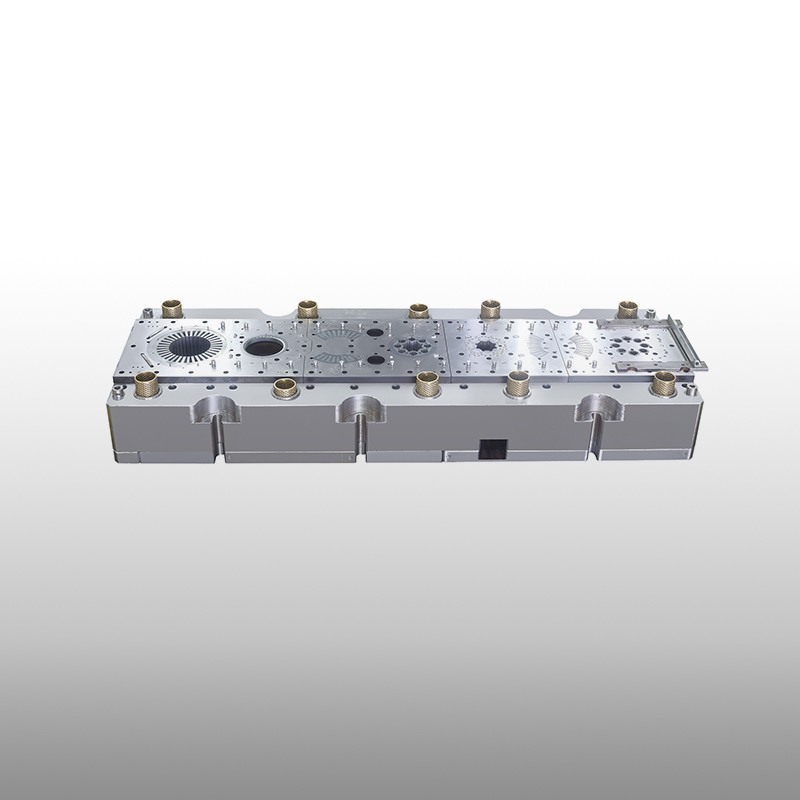

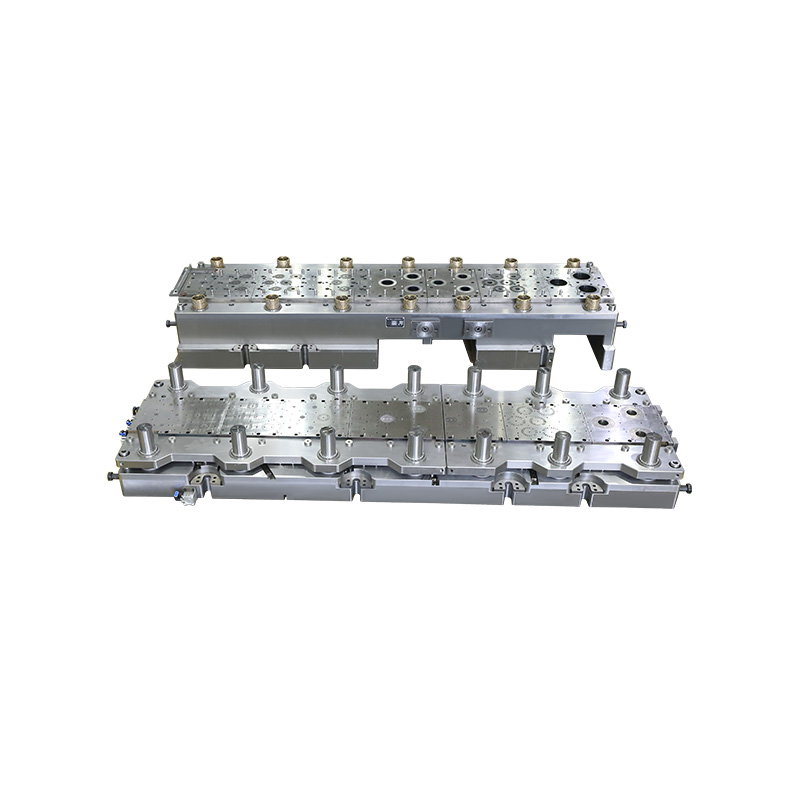

A Stamping Mold is a specialized tool used to shape or cut materials into specific forms through a mechanical pressing process. Manufacturers increasingly turn to stamping molds for their exceptional ability to produce high volumes of parts with consistent accuracy and repeatability. Whether you are creating intricate components for electronic devices, structural parts for vehicles, or consumer products, a Stamping Mold can be precisely tailored to meet exact design specifications and production requirements. This adaptability makes it an incredibly practical and versatile option for numerous production scenarios across various industries.

Not every stamping mold delivers the same performance level or operational results. Reputable manufacturers use engineering expertise, precision machining techniques, and high materials to create molds that resist wear, perform continuously under pressure, and maintain dimensional stability during extended production runs. Collaborating with a skilled stamping Mold Manufacturer helps ensure your tools are optimized for your specific material characteristics, production environment, and application needs.

Customization represents another significant advantage of modern stamping molds. While off-the-shelf tooling can sometimes approximate what you need, a custom Stamping Mold is designed and engineered from the ground up to finely match your part geometry, material type, production volume, and requirements. This high level of personalization not only reduces material waste but also shortens cycle times, secondary operations, and improves the overall quality of your output. A qualified stamping Mold Manufacturer will work closely with your engineering team to refine designs, select appropriate materials, and validate tool performance through comprehensive testing before committing to full-scale production.

Durability remains a critical consideration in stamping operations. These molds are subjected to high pressures, repetitive impacts, and continuous use, which can cause inferior tools to fail prematurely, resulting in unplanned downtime and additional costs. Selecting a robust Stamping Mold constructed from appropriate tool steels, carbides, or specialized alloys significantly enhances longevity and reduces unexpected production interruptions. Furthermore, a reliable Stamping Mold Manufacturer typically provides ongoing technical support for maintenance, repair, and refurbishment services, helping you extend the service life of your tooling investment and return on investment.

In addition to durability, contemporary stamping molds contribute substantially to overall production efficiency and operational excellence. With quicker setup times, smoother operation, reduced maintenance requirements, and compatibility with automated systems and Industry 4.0 technologies, a well-made Stamping Mold can help streamline your manufacturing process from start to finish. This becomes particularly important in industries where meeting tight tolerances, maintaining high-output demands, and ensuring consistency are critical to business success and customer satisfaction.

While the investment might be higher compared to standard tooling options, the payoff in terms of good parts, reduced material waste, decreased downtime, and lower per-unit cost can be substantial over the tool's lifespan. By selecting a trusted stamping Mold Manufacturer with proven experience and technical expertise, you gain not only a high-performance tool but also valuable technical support, industry knowledge, and reliable post-sale service.

If you are exploring ways to enhance your manufacturing capability, improve product, and increase operational efficiency, considering a custom Stamping Mold could be a productive step forward. It offers a powerful blend of precision, durability, and efficiency that can adapt to both current production requirements and future manufacturing challenges.