2025.10.17

2025.10.17

Industry News

Industry News

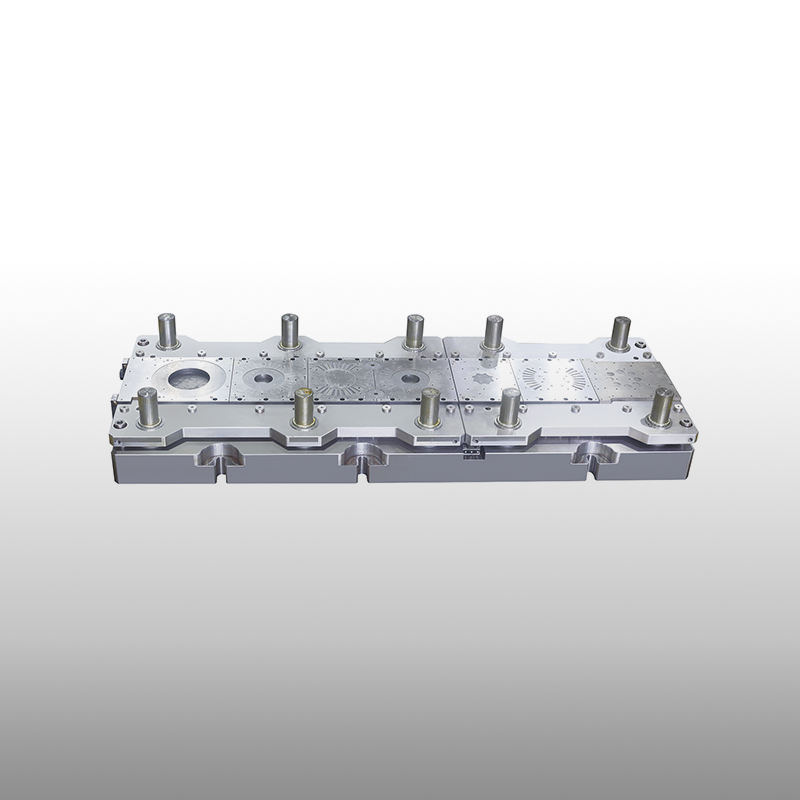

In today's competitive manufacturing landscape, companies across industries are constantly seeking ways to enhance their production processes. One question that often arises is how Mold Customization can contribute to improved operational efficiency. The answer lies in the tailored approach that custom tooling brings to manufacturing challenges, offering solutions that standard options frequently cannot provide.

When implemented properly, Mold Customization allows manufacturers to address specific production needs that off-the-shelf solutions cannot meet. A well-designed custom mold fits finely into your existing production workflow, reducing setup times and adjustments during operation. This seamless integration directly translates to less downtime and more consistent output. The right Mold Customization approach considers your specific material requirements, production volume, and standards to create tools that perform within your unique environment. By accounting for these factors during the design phase, manufacturers can avoid the compromises often associated with standardized tooling.

The expertise of your chosen Mold Customization Manufacturer plays a significant role in determining the efficiency gains you can achieve. An experienced manufacturer doesn't just produce molds according to specifications—they provide valuable insights into design improvements that can enhance performance and longevity. The collaboration between your engineering team and a qualified Mold Customization Manufacturer often results in solutions that streamline production while maintaining standards.

Another efficiency aspect of Mold Customization involves material utilization. This careful attention to detail reduces material costs and decreases the time spent on post-processing operations. The precision offered by proper Mold Customization means fewer rejected parts and less rework, contributing directly to overall production efficiency. Additionally, reduced material waste aligns with sustainable manufacturing practices, offering both economic and environmental benefits.

Maintenance and durability also factor into the efficiency equation. A custom mold designed with your specific production requirements in mind typically offers better durability and requires less frequent maintenance than generic alternatives. Working with a reputable Mold Customization Manufacturer ensures that your tools are built to withstand the demands of your production environment, reducing unexpected stoppages and maintenance-related delays. The use of materials and precision engineering in Mold Customization results in tools that maintain their performance characteristics over extended periods, providing consistent results throughout their lifespan.

The flexibility afforded by Mold Customization allows manufacturers to adapt quickly to design changes or new product introductions. Instead of searching for suitable off-the-shelf solutions or compromising on tooling performance, companies can work with their Mold Customization Manufacturer to develop tools that exactly match new requirements. This adaptability prevents production bottlenecks and maintains efficient operations through product transitions, helping manufacturers respond effectively to market changes and customer demands.

In high-volume production scenarios, the efficiency benefits of Mold Customization become particularly evident. Custom molds can be designed for faster cycle times, improved cooling characteristics, and easier part ejection—all factors that contribute to higher output rates. The investment in Mold Customization often proves worthwhile through sustained efficiency improvements over the tool's lifespan. Furthermore, the ability to produce more parts per hour without sacrificing directly impacts profitability and competitive positioning.

The technical support provided by a specialized Mold Customization Manufacturer can help optimize your entire production process. From design consultation to troubleshooting and maintenance advice, this partnership approach ensures that your tooling continues to support efficient operations long after the installation. Regular maintenance guidance and prompt technical assistance can significantly reduce downtime and extend tool life, contributing to long-term operational efficiency.