2025.10.24

2025.10.24

Industry News

Industry News

In modern manufacturing, efficiency and precision are more important than ever. Companies across sectors, from automotive to consumer goods, are constantly looking for methods to optimize their production lines, reduce waste, and maintain high productivity. One solution that frequently comes up in these discussions is the use of a Custom Metal Mold. But how exactly can it help make your manufacturing process more streamlined and effective?

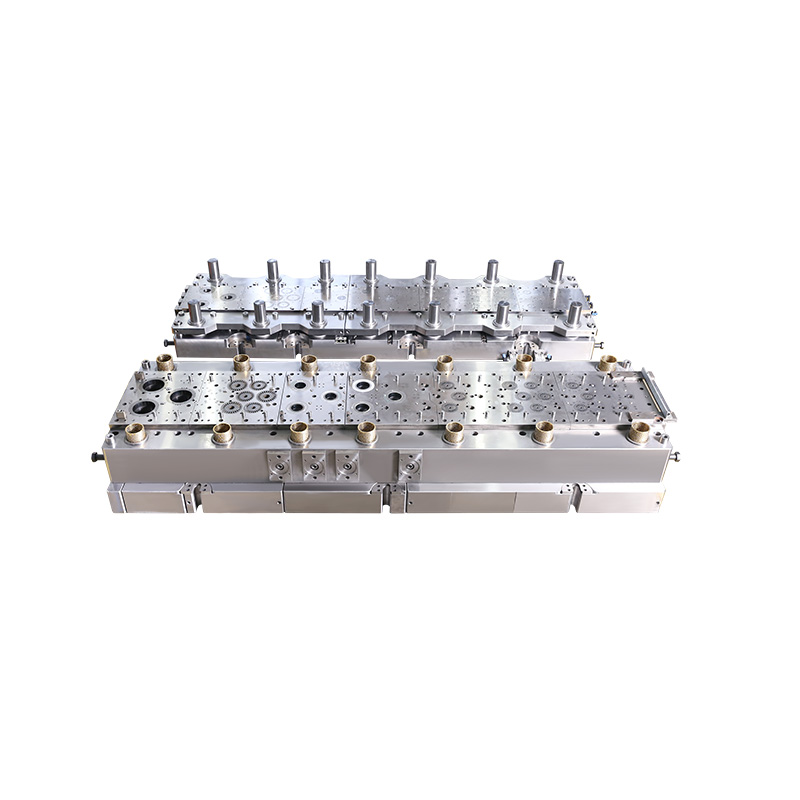

The primary advantage of a Custom Metal Mold lies in its ability to be designed and built for a specific application. Unlike generic, off-the-shelf molds, a Custom Metal Mold is engineered to match your part design, material properties, and production volume. This tailored approach reduces the need for adjustments, rework, or secondary processing, which in turn shortens cycle times and increases throughput. By integrating seamlessly into your existing setup, a Custom Metal Mold can help eliminate bottlenecks and improve the overall flow of your manufacturing process.

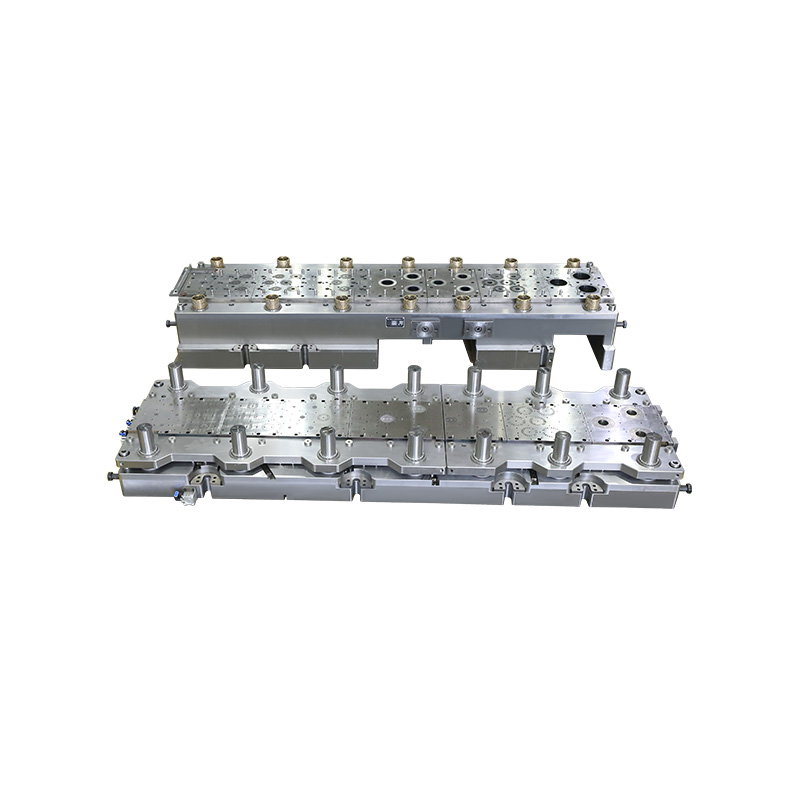

The success of this approach heavily depends on working with a knowledgeable Custom Metal Mold Manufacturer. An experienced manufacturer doesn't just supply a tool—they collaborate with you to understand your production challenges and goals. This partnership ensures that the Custom Metal Mold is optimized for your unique requirements, whether you're producing intricate components for aerospace or high-volume parts for the automotive industry. The right Custom Metal Mold Manufacturer will also advise on material selection, mold design, and maintenance strategies, all of which contribute to long-term operational efficiency.

Another way a Custom Metal Mold enhances manufacturing efficiency is through improved part consistency. Because these molds are precision-made to exact specifications, they produce parts with tighter tolerances and fewer defects. This means less time spent on inspection, rework, or scrap disposal. Over time, the reduction in wasted materials and labor leads to significant cost savings and a smoother, more predictable production rhythm.

Durability is another factor that supports process streamlining. A high Custom Metal Mold, especially one developed in partnership with a reputable Custom Metal Mold Manufacturer, is built to withstand rigorous use over extended periods. This robustness translates to less frequent mold changes, reduced unplanned downtime, and lower maintenance costs. In high-volume environments, where every minute of downtime counts, the reliability offered by a well-made Custom Metal Mold can make a noticeable difference in overall productivity.

Flexibility is an often-overlooked benefit. As product designs evolve or new materials are introduced, having a Custom Metal Mold allows for easier adaptation. This agility helps companies respond more quickly to market changes without major disruptions to their manufacturing process.

It's worth highlighting the role of the Custom Metal Mold Manufacturer in ongoing support and optimization. From design and prototyping to production and maintenance, a dedicated manufacturer provides valuable expertise that helps keep your operations running smoothly. Their technical support can assist in troubleshooting issues, implementing improvements, and planning for future capacity needs—each of these elements contributing to a more efficient and streamlined manufacturing process.

Integrating a Custom Metal Mold into your production system, especially when developed with a proficient custom Metal Mold Manufacturer, can significantly enhance operational efficiency. Through precision design, consistent output, extended durability, and adaptive flexibility, this approach supports a more streamlined, cost-effective, and responsive manufacturing process.