2025.10.27

2025.10.27

Industry News

Industry News

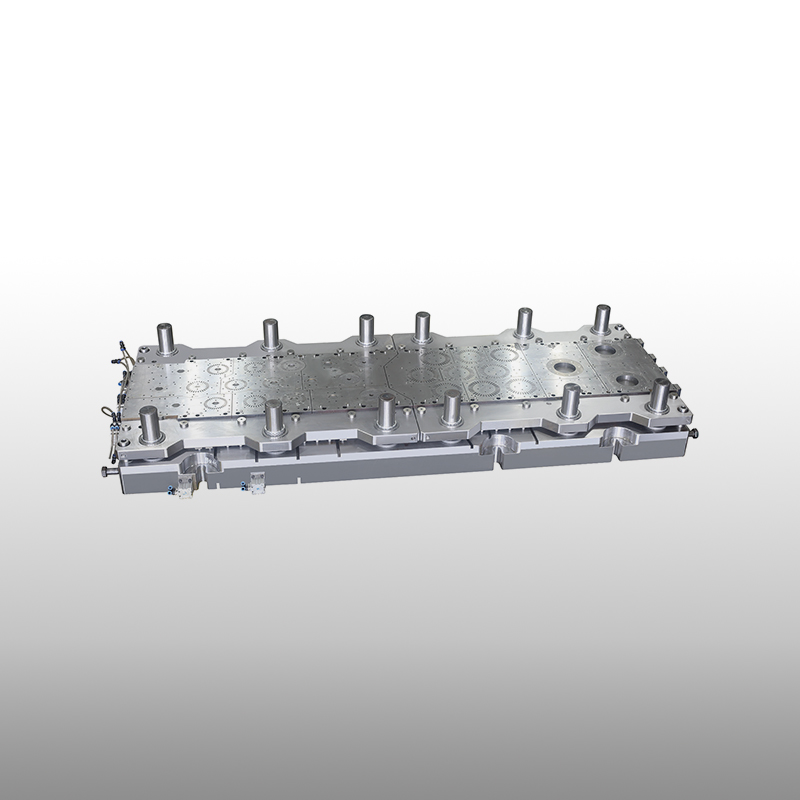

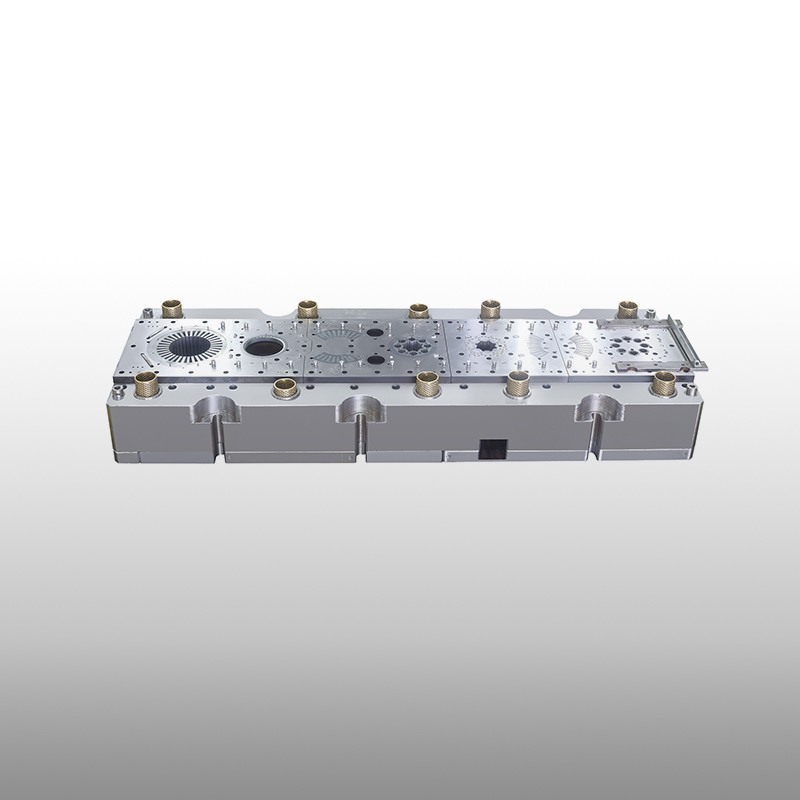

A high-progressive stamping die is a highly specialized tool engineered to perform a sequence of multiple operations—such as punching, cutting, bending, drawing, and coining—within a single, continuous process. The raw material, typically a coil of metal strip, is fed through the die. With each stroke of the press, the strip advances to a new station where a specific operation is performed. By the time the strip exits the die, a finished or nearly finished part is produced. This methodology enables the creation of complex components in one automated cycle, which can cause a substantial increase in output rates while consistently maintaining tight dimensional tolerances. It is for this reason that industries with high-volume demands, such as automotive, electronics, and appliance manufacturing, frequently rely on high-progressive stamping die systems to meet their production targets without compromising on part quality and consistency.

The performance, longevity, and reliability of the die are factors that depend greatly on the expertise and capability of your chosen high-progressive stamping die manufacturer. Not all suppliers possess the necessary engineering depth, technological resources, and practical experience to produce dies that perform reliably under continuous high-pressure and high-cycle conditions. A manufacturer with a strong reputation will not simply sell a standard product; they will work closely with your engineering team to understand your specific production goals, material specifications, part complexity, and quality requirements. This collaborative approach is essential for ensuring that the die design is optimized for both dimensional accuracy and long-term operational stability, creating a tool that is tailored to your unique application.

Material efficiency presents another considerable benefit. A well-engineered high-progressive stamping die can markedly reduce material scrap through optimized strip layout and precise cutting actions. The manufacturer's design team will meticulously plan the arrangement of parts on the metal strip to minimize waste, which is particularly important when working with expensive or specialty metals. The expertise offered by a qualified high-progressive stamping die manufacturer often includes a detailed material utilization analysis, which can cause significant cost savings over the lifespan of the tooling, making the operation more economical and sustainable.

Durability and maintenance are also critical considerations. High-speed, high-volume operations exert tremendous mechanical stress on all tooling components. A high-progressive stamping die constructed from high-grade, hardened tool steels and designed with balanced load distribution and inherent wear resistance in mind will have a longer operational life and will require less frequent sharpening or component replacement. Your choice of manufacturer profoundly influences not only the initial quality of the die but also the long-term availability of technical support, ready access to spare parts, and professional refurbishment services, which are vital for minimizing production downtime.

Incorporating a high-progressive stamping die into your manufacturing line can offer notable benefits in terms of production speed, part accuracy, and operational efficiency. However, achieving these good results is contingent upon a close collaboration with a capable and experienced high-progressive stamping die manufacturer. Such a partner can deliver a robust, custom-designed solution that is meticulously tailored to your specific needs. If high-volume production with consistent quality is a central priority for your operations, this technology warrants a thorough and detailed evaluation.