2025.12.05

2025.12.05

Industry News

Industry News

Stamping Die Design influences far more than the shape of a finished metal part. Many buyers in automotive, hardware, and appliance production are curious about how this process actually works and what separates one supplier from another. As more companies shift toward customized production and faster delivery cycles, the role of reliable Stamping Die Design Manufacturers becomes even more noticeable across the supply chain. Below are several angles buyers often wonder about—and answers that help clarify what's happening behind the scenes.

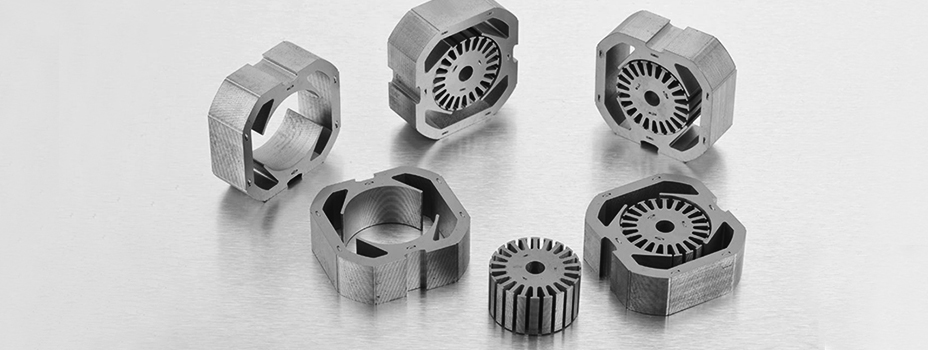

A stamping die is not just a tool; it's a long-term production asset. Buyers often wonder why the same part can perform well in one facility yet cause delays in another. The difference usually lies in how the die was originally designed. A proper Stamping Die Design considers material flow, stress points, expected production volume, and the type of equipment used on the shop floor.

This is also where mold customization concepts offer insight. Just like a Custom Metal Mold is tailored to fit a specific production requirement, stamping dies benefit from the same kind of precision thinking. When a die is shaped with the end use in mind, it produces more consistent parts and reduces adjustments during production. For industries running thousands of cycles per day, that consistency supports smoother operations and fewer unwanted stoppages.

Many companies compare suppliers based on delivery time and price, but experienced buyers look deeper. They want to know whether the manufacturer can support complex geometries, long-life tooling, and different grades of metal materials. A manufacturer that invests in great machining, simulation, and measurement tools usually delivers greater reliability over time.

This is also where the thinking behind custom metal molds becomes relevant. These molds are built to handle repeated use in challenging conditions, and stamping dies require similar durability. Manufacturers who understand both areas typically create tools that perform with greater stability across high-volume production cycles.

Buyers also ask about communication. Clear updates during the design and build process help avoid misunderstandings and give production teams confidence before the die ever reaches the press.

The demand for mold customization and tailored tooling has grown across industries. Companies want solutions that match their specific part geometry instead of adapting to generic tools. Stamping Die Design follows the same trend. Customization allows each part of the die—cutting edges, forming stations, and pilot structures—to match the material behavior and production requirements of the final product.

Industries such as automotive and electronics often request tighter tolerances, and this is where customization becomes valuable. When the die geometry aligns with the characteristics of materials like stainless steel or aluminum, the production line runs more smoothly. The same idea applies to stainless steel casting molds, which rely on accurate shaping to deliver clean, repeatable results. While the manufacturing processes differ, the expectation for precision overlaps in both fields.

Manufacturers with strong internal engineering teams tend to respond better to these expectations. Their experience with custom metal molds or stainless steel tooling often translates into smoother planning and faster adjustments during die development.