2025.12.12

2025.12.12

Industry News

Industry News

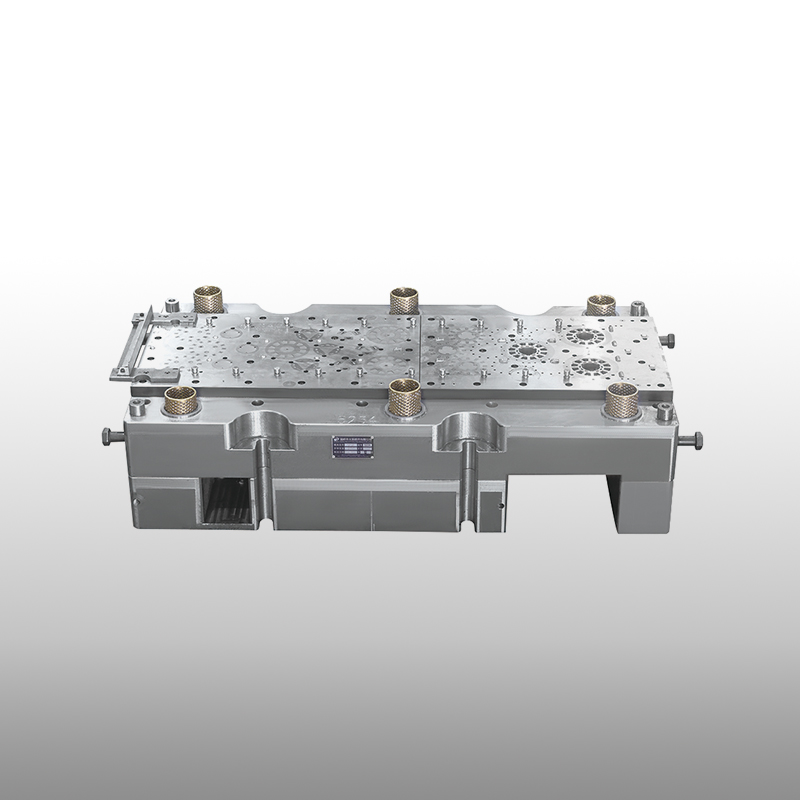

A Stamping Die is often the backbone of metal forming projects, especially for companies that depend on consistent shapes, stable tolerances, and smooth production flow. Many industrial buyers understand the pressure of meeting tight schedules and dealing with rising material costs. They want parts that match drawings without repeated adjustments. They want fewer production interruptions. And they need a partner who understands how a well-built die influences long-term reliability.

One of the biggest issues buyers face is the gap between design intent and final product. A Stamping Die built without proper customization often creates part variations, forcing operators to recalibrate machines and increasing scrap rates. This is where experienced Stamping Die Manufacturers add real value.

Through mold customization and great metal mold design, they shape each die to the exact geometry needed for your parts. A well-crafted die reduces the back-and-forth typically seen during trial runs. For industries such as automotive or aerospace, this level of alignment means components fit their assemblies better, reducing delays during downstream processes.

Custom metal molds provide the added advantage of handling complex forms while holding stable tolerances. Their durability also supports repetitive use in demanding production environments, keeping output consistent even under heavy workloads.

Another common pain point is how often dies require maintenance. Frequent repairs slow production and drive up operating costs. When a Stamping Die is engineered with durable materials and proper heat treatment, its lifespan increases, and operations become smoother.

This is a key area where strong Stamping Die Manufacturers differentiate themselves. They design dies to handle constant pressure, friction, and high-speed cycles. The goal is not only to run today's job well but also to last through thousands of cycles with stable performance.

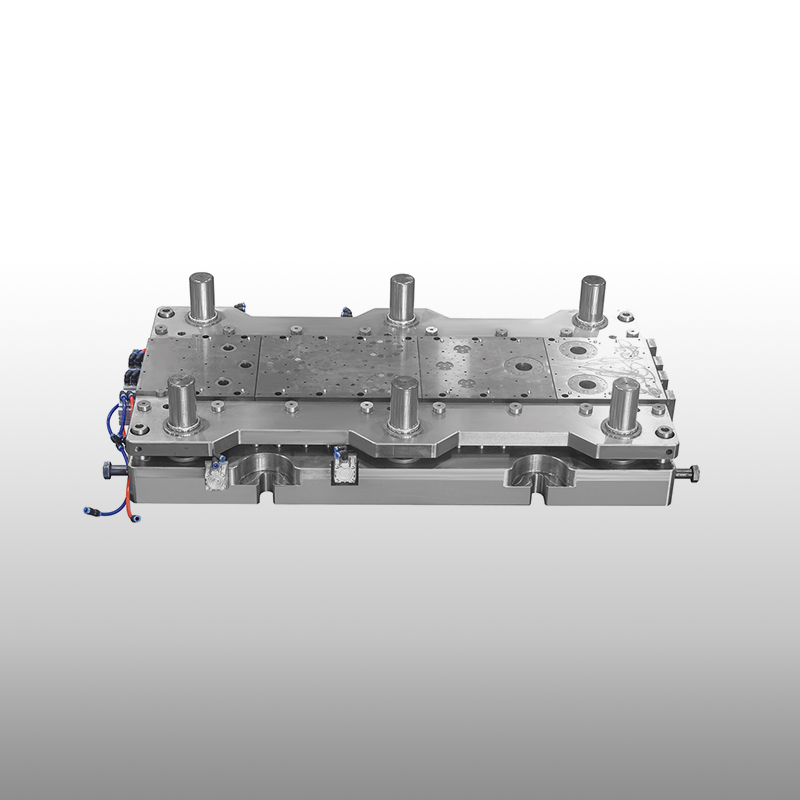

For companies using stainless steel molds or custom metal molds in related processes, material reliability is just as important. These molds withstand harsh environments and maintain dimensional stability for a long time, making them suitable for projects in marine, food processing, medical devices, and other demanding sectors.

Buyers often need dies for different product lines, short-run prototypes, or new product testing. Traditional tooling is not always flexible enough, which to delay when adapting to new shapes or material types.

With mold customization services, companies can quickly adjust tooling to support new production needs. Whether for automotive brackets, consumer appliance parts, or small mechanical components, a flexible Stamping Die setup helps keep product development moving forward.

Some projects may require tight forms or fine details. Custom metal molds handle these requirements well due to their ability to shape intricate designs. When paired with a properly built Stamping Die, manufacturers can achieve a smooth workflow from prototyping to larger production volumes.

High-volume projects place pressure on both the die and the production team. A Stamping Die that lacks stability can slow the entire line. Buyers often report issues such as uneven forming, burrs, edge warping, or inconsistent thickness.

Working with skilled Stamping Die Manufacturers helps reduce these concerns. They run detailed analyses on metal flow, stress points, and tooling wear. This preparation supports predictable output and reduces downtime.

When companies invest in a well-designed Stamping Die, they gain smoother operations, better part consistency, and a more controlled production environment. For businesses managing tight schedules or complex product lines, the right partnership with capable Stamping Die Manufacturers brings long-term stability to daily manufacturing work.