2025.12.19

2025.12.19

Industry News

Industry News

A Precision Stamping Mold plays a central role in motor core production, especially for factories handling large-volume projects and varying design requirements. Many manufacturers struggle with unstable core dimensions, high scrap rates, and the pressure to keep production lines running smoothly. A strong supplier relationship helps buyers reduce these risks and make their workflow more predictable. This is where a capable Precision Stamping Mold Company becomes valuable, especially one with a long-term focus on progressive stamping technology.

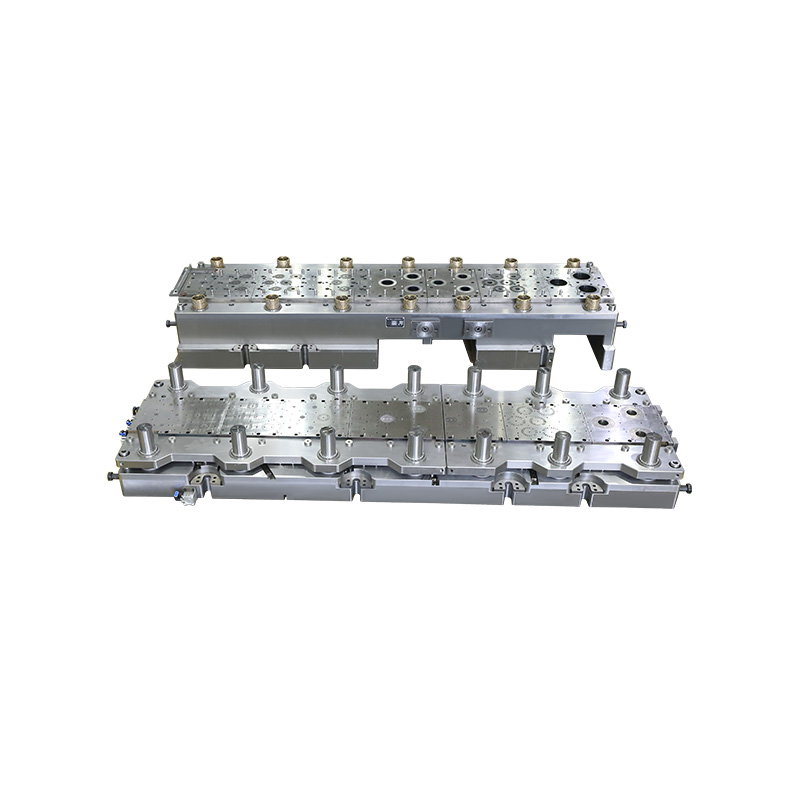

Wenling Dajing Mold Co., Ltd. has devoted more than two decades to high-speed progressive designs and custom motor core tools. The company has built experience across single-row to five-row structures, making it easier for customers to handle different forming demands without constant redesign. Buyers searching for stable performance, clean punching, and strong support for automated lines usually turn to suppliers with this level of maturity.

Motor core production seldom follows a single pattern. Factories run multiple product types at once—water pump motors this week, AC compressor motors the next. A Precision Stamping Mold designed with the right engineering depth supports this variation without forcing frequent machine adjustments.

Dajing builds molds that process stator and rotor diameters from Φ12 to Φ720mm, which helps factories cover a wide product range without sourcing new tools for each project. For users dealing with Φ12 to Φ260mm cores, the possibility to achieve slant slots, stepped hole punching, and self-locking designs brings clear process advantages. This reduces the need for extra tooling stations and cuts downtime during transitions.

High-speed lines depend heavily on mold accuracy. When molds lose alignment or create uneven edges, the entire line slows down. This is a major pain point for many buyers, especially when handling large orders under tight delivery schedules.

A Precision Stamping Mold Company with long-term research in progressive stamping supports a smoother run by controlling strip layout, guiding accuracy, and tool strength. Dajing has spent decades refining these factors, blending precision mold design with lean production and automation. For the buyer, this means fewer interruptions and a more predictable daily workflow.

Stamping Mold Company with long-term research in progressive stamping supports a smoother run by controlling strip layout, guiding accuracy, and tool strength. Dajing has spent decades refining these factors, blending precision mold design with lean production and automation. For the buyer, this means fewer interruptions and a more predictable daily workflow.

When customers move into heavier automation, they often need molds that stay stable even under continuous pressure. This is where Dajing's experience in multi-row technology becomes useful. Whether single-row or five-row, the molds are engineered to resist wear, handle repeat cycles, and keep material flow steady.

Many manufacturers struggle with molds that look good on paper but behave poorly in real production. This usually happens when suppliers lack hands-on experience with motor core projects. A seasoned Precision Stamping Mold Company approaches customization differently—it focuses on how the mold performs inside a running workshop.

With years of exposure to Y-series motors, generators, stepper motors, shaded pole motors, brushless DC models, and inverter designs, Dajing adapts each mold to structural differences that affect punching accuracy. Buyers working with mixed product lines often benefit from this flexibility, as they avoid long adjustment cycles during trial runs.

By combining R&D investments with automation and lean production, Dajing supports customers who want to expand output without adding excessive labor or dealing with unstable mold wear.