2025.12.25

2025.12.25

Industry News

Industry News

Many manufacturers reach a point where standard molds can no longer support rising product expectations. Mold Customization helps solve this gap by shaping tooling around your actual production needs instead of forcing your processes to adapt to generic designs. At Wenling Dajing Mold Co., Ltd., more than twenty years of research into high-speed progressive stamping dies has shown us how tailored molds directly support stable production, better forming accuracy, and cleaner stamping results for motor core parts.

Growth often brings new product sizes, new motor types, and higher output demands. A Mold Customization Company provides technical flexibility, which becomes valuable when you need single-row to five-row stamping solutions or when your project requires both precision and repeatability. Dajing's experience in progressive technology and automatic production lines helps companies move from small-scale development to stable mass production without unnecessary downtime or redesign cycles.

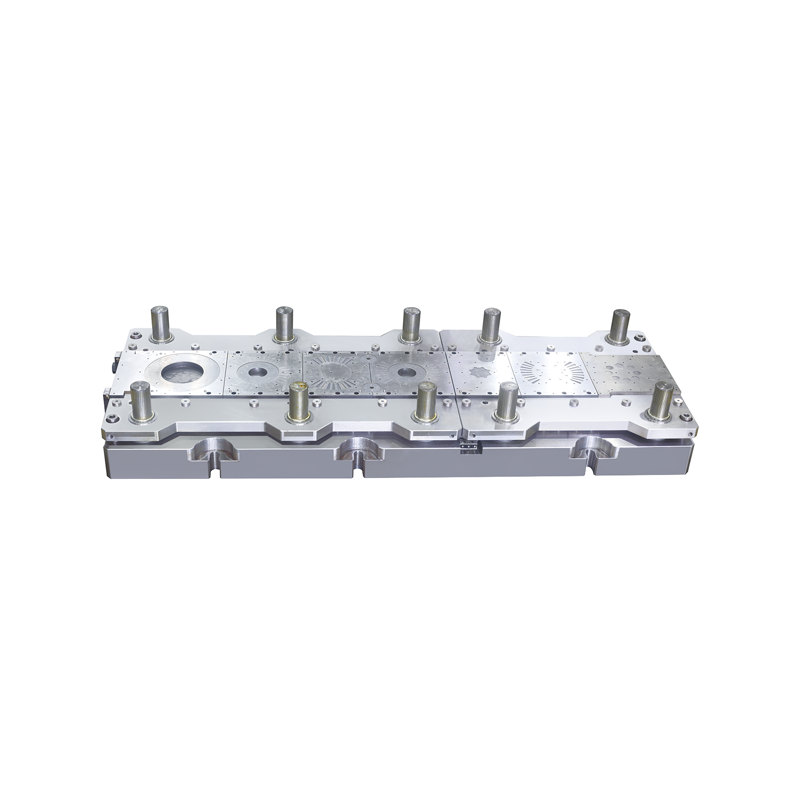

Motor core stamping needs speed, tight tolerances, and consistency across long production runs. Mold Customization helps manufacturers address common challenges such as burr control, slot accuracy, and material utilization. At Dajing, our progressive dies handle diameters from Φ12 to Φ720mm, providing room for a wide variety of stator and rotor core designs. Features such as self-locking, slant slots, and stepped hole punching allow customers to develop competitive motor products with fewer adjustments during assembly.

When molds are built around your actual operating environment and machine setup, there are fewer surprise issues later. This applies to high-speed lines, automated feeding systems, or multi-layer core stacking structures. As a long-term Mold Customization Company, Dajing works closely with engineering teams to refine early concepts before tooling begins. This reduces trial cycles and shortens the path to stable mass production.

Many brands struggle to upgrade to faster stamping speeds because their old molds cannot keep up with the demands of modern equipment. Dajing invests heavily in progressive stamping R&D, optimizing structures from single-row to five-row layouts. Mold Customization allows customers to adopt new production methods without needing a full equipment overhaul.

Material waste becomes costly in long-term stamping. When a mold is customized for a specific coil width, thickness, and stamping order, alignment becomes more accurate, and scrap naturally decreases. For motor manufacturers who run large batch orders—such as washing machine motors, air-conditioning compressor motors, or BLDC motors—this cycle measures cost improvements.

Product lines expand over the years. A Mold Customization Company helps manufacturers respond to new market requests, such as EV motors, compact home appliance motors, or regional variations in rotor design. Thanks to our long export history, Dajing supports customers across different technical standards while maintaining stable quality for mass production.

Automation amplifies mistakes when molds are not aligned with the machine's behavior. Customizing the mold structure helps stabilize feeding, reduce misfeeds, and keep stamping speed consistent. Our combination of progressive dies with automated production systems has helped customers reduce downtime and maintain smoother output during complex stamping sequences.

With precise forming and reliable stamping sequences, parts remain consistent across thousands of cycles. This is valuable for companies supplying automotive motors, generator cores, or industrial motors where long-term stability matters. By focusing on structural accuracy and repeatability, Dajing helps companies protect product quality over extended production periods.