2026.01.02

2026.01.02

Industry News

Industry News

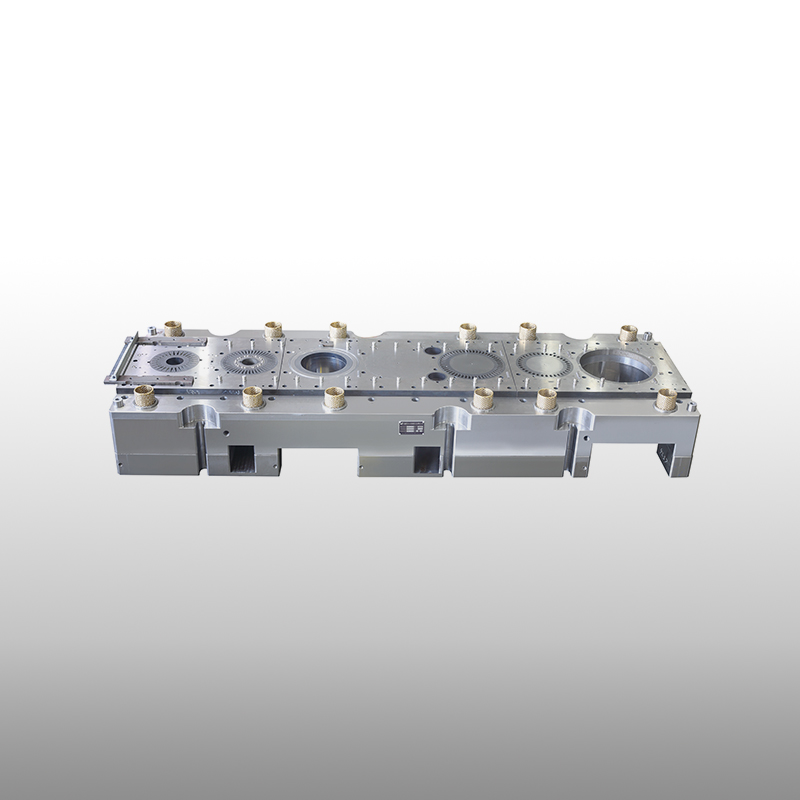

Manufacturers across the automotive, electronics, and appliance sectors keep facing the same pressure: stable quality at high volume without rising production costs. A High Speed Progressive Stamping Die often becomes the backbone of that upgrade because it delivers steady output, predictable performance, and long-term durability. Behind this capability is the foundation laid by a factory experienced in mold customization, metal mold engineering, and stainless steel mold production. These competencies allow customers to move from design ideas to reliably manufactured parts with fewer surprises along the way.

A High Speed Progressive Stamping Die is frequently selected when a project demands fast cycle times paired with tight dimensional requirements. Many buyers come to us with similar pain points: inconsistent part accuracy, downtime caused by worn tooling, or a stamping process that becomes unstable once volume ramps up. These issues usually surface when the die structure does not match real production conditions. Through custom metal mold engineering and targeted adjustments to plate thickness, material grades, guiding systems, and lubrication paths, these weaknesses can be removed before the die ever reaches the press.

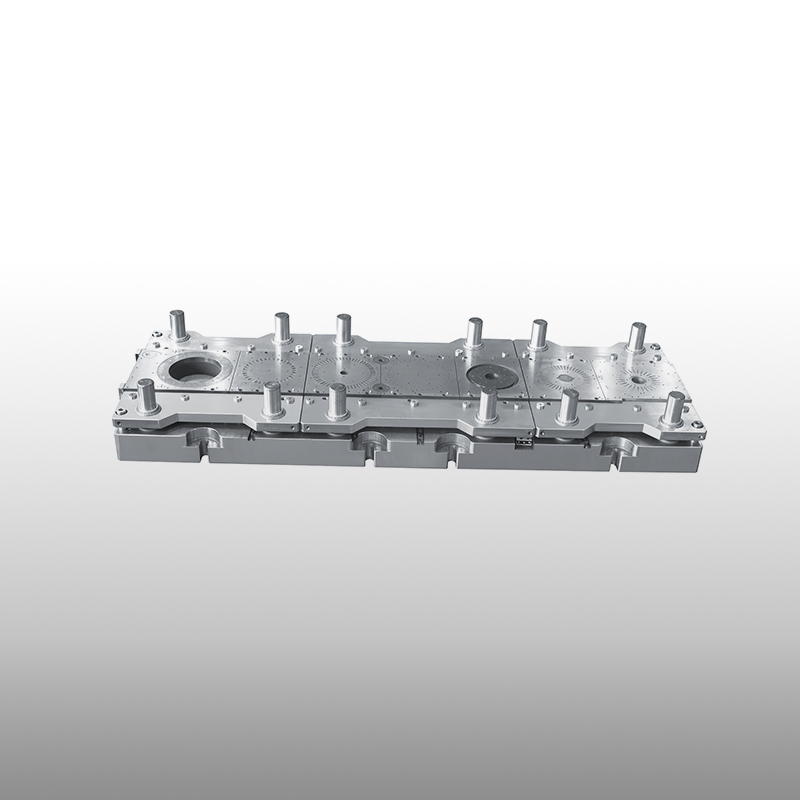

High-volume lines run at high speed only when each station of the die performs smoothly. A properly designed High Speed Progressive Stamping Die keeps feed movement aligned, reduces mis-strikes, and maintains consistent forming across hundreds of thousands of cycles. When combined with hardened steel used in our custom metal molds, the die can withstand demanding loads without deformation. This stability directly answers a common user concern: how to keep production predictable even when shifts rotate, and operators vary in experience.

Many clients come to us with existing drawings that do not fully reflect what happens on the shop floor. Mold customization offers a more practical route, allowing the die design to be adapted to the exact press model, feeding direction, raw material width, and product tolerance window. This flexibility helps reduce waste and keeps parts within specification without repeatedly adjusting machine settings. Whether the project aims for prototyping or high-volume output, customization allows the High Speed Progressive Stamping Die to fit the job rather than forcing the job to fit the die.

Durability is influenced not only by die layout but also by material selection. Our experience with custom metal molds and stainless steel casting molds provides an understanding of how steels behave under repetitive stress. Heat treatment depth, wear-resistant inserts, sharpening allowances, and parting surface geometry all contribute to longer maintenance intervals. Buyers often request support in reducing the frequency of downtime, and proper material engineering is one of the strongest levers. It supports smoother production and gives the die a longer working life, reducing the total cost per part over time.

Require cleaner edges, tighter tolerances, and more stable forming. A High Speed Progressive Stamping Die can integrate trimming, piercing, bending, and shaping within one structure, simplifying the workflow. This reduces part handling, minimizes scrap risk, and shortens overall cycle time. Customers often highlight that this approach allows teams to keep the production line more compact and easier to manage.

Our factory continues to refine manufacturing quality by integrating mold customization, custom metal mold production, and stainless steel mold engineering. These capabilities support the functional strength and performance reliability expected from modern tooling. A High Speed Progressive Stamping Die built with this foundation offers the consistency, efficiency, and durability needed for today's competitive manufacturing environment.