2025.06.13

2025.06.13

Industry News

Industry News

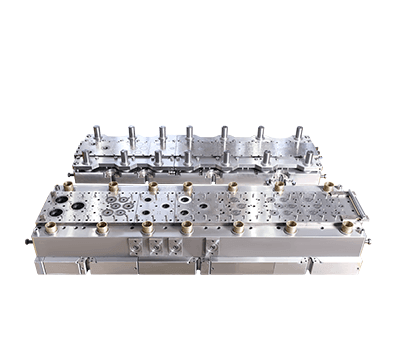

In the demanding world of manufacturing, the ability to translate intricate product visions into tangible, high-volume reality is paramount. While many processes exist, Custom Metal Mold technology stands as a cornerstone for achieving this, particularly when the design involves sophisticated internal structures or delicate thin-walled components. The inherent capability of a well-engineered Custom Metal Mold to master complex geometries unlocks design freedom and functional performance.

The true genius of Custom Metal Mold fabrication lies in its sophisticated mechanical orchestration. Unlike simpler tooling, a Custom Metal Mold is not merely a cavity; it's an intricate system designed to actively shape and release parts that defy conventional manufacturing constraints. This is especially critical for parts featuring undercuts, side holes, internal threads, or intricate internal channels – features impossible to achieve with basic two-part molds.

Consider a plastic housing requiring robust internal snap-fits or a medical device component with complex internal fluid pathways. A standard mold would fail. This is where the specialized engineering of a Custom Metal Mold comes into play. Through the strategic integration of moving components within the mold base itself – mechanisms like sliding cores (sliders), angular lifters (lifters), or even motorized unscrewing devices – the Custom Metal Mold dynamically creates the necessary space for these features during molding and then precisely retracts to allow flawless ejection. Designing and machining these mechanisms to operate reliably over hundreds of thousands of cycles demands exceptional expertise in Custom Metal Mold engineering. The precision of these moving elements, meticulously crafted and hardened, is fundamental to the Custom Metal Mold's success in forming complex internal structures consistently.

Similarly, external geometries demanding deep draws, sharp corners, or complex surface textures rely heavily on the precision machining and surface finishing capabilities intrinsic to high-quality Custom Metal Mold production. The mold cavity becomes the physical blueprint, and every micron of its surface is critical. Advanced CNC machining, EDM (Electrical Discharge Machining), and precision polishing ensure that the Custom Metal Mold perfectly replicates the intended design, down to the finest detail, whether it's a high-gloss finish or a specific grain texture.

Beyond complex shapes, the mastery of thin-wall molding represents another significant frontier conquered by advanced Custom Metal Mold technology. Producing lightweight, rigid components with walls often measuring less than a millimeter thick presents unique challenges: ensuring complete cavity fill before the material solidifies, preventing warpage, and maintaining dimensional stability across vast production runs. Success hinges entirely on the Custom Metal Mold's design and execution.

The foundation lies in the mold material itself. High-performance tool steels, selected for specific applications like high thermal conductivity or exceptional hardness, form the core of a capable Custom Metal Mold for thin-wall applications. However, material choice is just the start. The real engineering prowess manifests in the mold's cooling system design. Optimizing the placement, size, and circuitous routing of cooling channels within the Custom Metal Mold is a science. Efficient, balanced heat extraction is non-negotiable for achieving the rapid cycle times demanded by thin-wall production and for ensuring uniform cooling to minimize stresses and warping. A poorly cooled Custom Metal Mold simply cannot produce viable thin-wall parts consistently.

Precision machining again plays a starring role. The cavity and core of the Custom Metal Mold must be machined to incredibly tight tolerances to ensure uniform wall thickness – a critical factor for both structural integrity and aesthetic consistency. Even minor variations can to filling imbalances or visible defects. Furthermore, the Custom Metal Mold must be robustly constructed to withstand the high injection pressures required to force molten material into these thin sections rapidly before it cools. The structural integrity of the Custom Metal Mold frame and support systems is paramount under these demanding conditions.

The venting design within the Custom Metal Mold also becomes crucial for thin walls. Trapped air must escape instantaneously as the fast-flowing melt fills the narrow cavity. Insufficient venting s to burns, incomplete filling (short shots), or poor surface quality. The Custom Metal Mold engineer must incorporate precise, strategically located vents that allow air out without allowing material to flash.

Ultimately, the value proposition of a sophisticated Custom Metal Mold for complex geometries and thin walls lies in its ability to deliver consistent, high-volume production of parts that meet exacting specifications. It transforms challenging designs from prototypes or low-volume lab curiosities into commercially viable products. Whether enabling lighter and stronger automotive components, miniaturized and intricate electronics housings, complex medical device parts requiring biocompatibility, or consumer goods with demanding aesthetic and functional needs, the Custom Metal Mold is the enabling technology.

Investing in a properly designed and manufactured Custom Metal Mold represents a strategic commitment to quality, efficiency, and design innovation. It leverages the precision of modern machining, the science of material flow and thermal management, and the art of mechanical design within the mold itself. For parts demanding intricate internal features or the structural elegance of thin walls, the capabilities of a well-executed Custom Metal Mold are indispensable. The Custom Metal Mold is not just a tool; it's the meticulously crafted foundation upon which complex, high-performance plastic, metal, or composite parts are reliably and repeatedly built. The continuous evolution of Custom Metal Mold technology pushes the boundaries of what is manufacturable, enabling engineers and designers to realize increasingly ambitious visions for the products of tomorrow. The journey from complex design to mass-produced reality invariably relies on the precision and ingenuity embedded within the Custom Metal Mold.