2026.01.16

2026.01.16

Industry News

Industry News

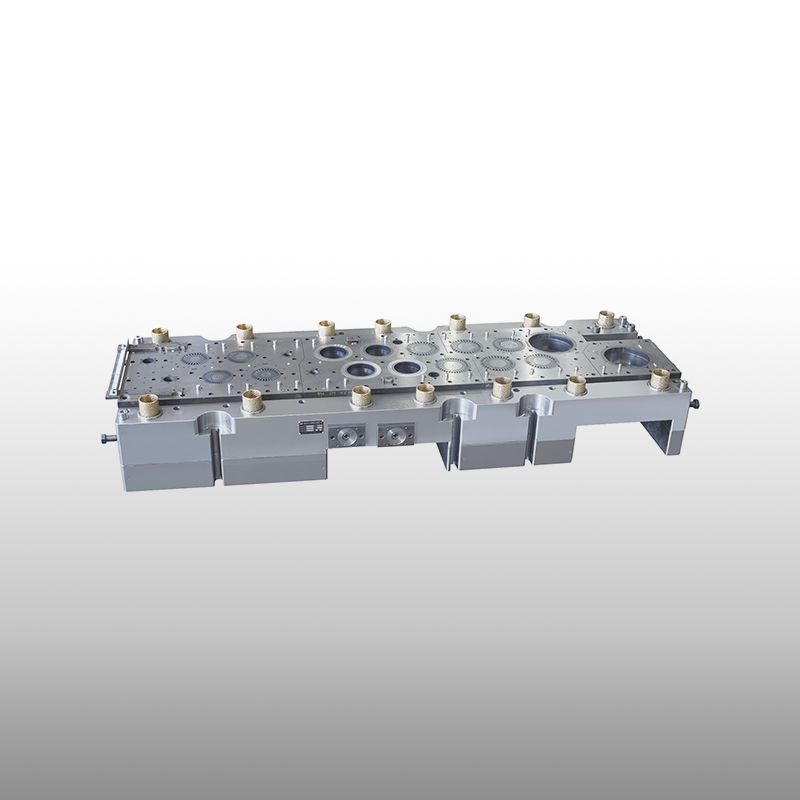

In modern motor core manufacturing, production speed and precision are closely linked. A reliable stamping mold can significantly impact output while minimizing material waste. Factories that invest in progressive designs, like our 155 Double-row Precision Progressive Metal Stamping Die, can handle multiple products without changing molds, streamlining operations, and lowering overall costs.

Every stamping mold experiences wear over time, but proper design choices can extend its working life. Blade material, mold structure, and guide precision all play a role. For example, molds using high-hardness DJ40 blades and precision guide parts maintain cutting accuracy longer, achieving a blade die life of over 5 million strokes per 0.1mm. Regular maintenance and controlled blanking speeds also help reduce stress and ensure consistent output.

Motor cores often require specialized features, such as skewed slots, self-locking elements, or step-hole punching. A flexible stamping mold factory can produce laminations ranging from Φ12 to Φ720mm, accommodating single-row, double-row, or multi-row layouts. Progressive dies with multiple slots allow simultaneous processing of stators and rotors. This approach not only saves time but also simplifies production planning for diverse designs.

Choosing a stamping mold isn't just about size or shape—it's about efficiency and precision. Considerations include cutting-edge height, concentricity, rivet force, and protection devices. Our molds feature three-plate mold bases with ball guides and misfeed detection, reducing errors and maintaining uniform output. For manufacturers handling varying rotor diameters, the ability to interchange mold plates without downtime is a significant advantage.

Greats in mold design enhance precision, reduce burrs, and minimize material loss. Punches are polished with specialized processes to remove oxidation layers, while guide parts maintain concentricity within 0.05mm. High-speed operations can reach 280 punches per minute with minimal quality variation. Incorporating misfeed protection, rotor control devices, and precise conveyor output ensures that both speed and accuracy meet production goals without compromising reliability.

Every project has unique requirements, and a stamping mold factory that offers customization makes a difference. By working from customer-provided drawings or samples, molds can be tailored for internal riveting, skewed slots, or large rotary internal riveting. Spare parts are often supplied at 30% of the wearing components, ensuring minimal downtime. This level of customization helps manufacturers adapt to evolving market demands while maintaining consistent quality.

A stamping mold is more than a tool—it's a central part of motor core production strategy. Factories that combine high-precision design, flexible customization, and great protection features can produce complex laminations efficiently, reducing costs while maintaining consistent output. Partnering with a skilled stamping mold factory ensures access to durable dies, accurate processes, and tailored solutions for a wide range of motor core applications.

Choosing the right stamping mold and partnering with an experienced stamping mold factory can significantly impact production efficiency and product quality. By focusing on precision design, flexible customization, and durable materials, manufacturers can handle complex motor core requirements with minimal interruptions. Thoughtful mold selection and proper maintenance help maintain consistent output, reduce waste, and adapt to evolving production needs. Investing in great molds ensures a smoother workflow and reliable results across various applications.