2026.01.23

2026.01.23

Industry News

Industry News

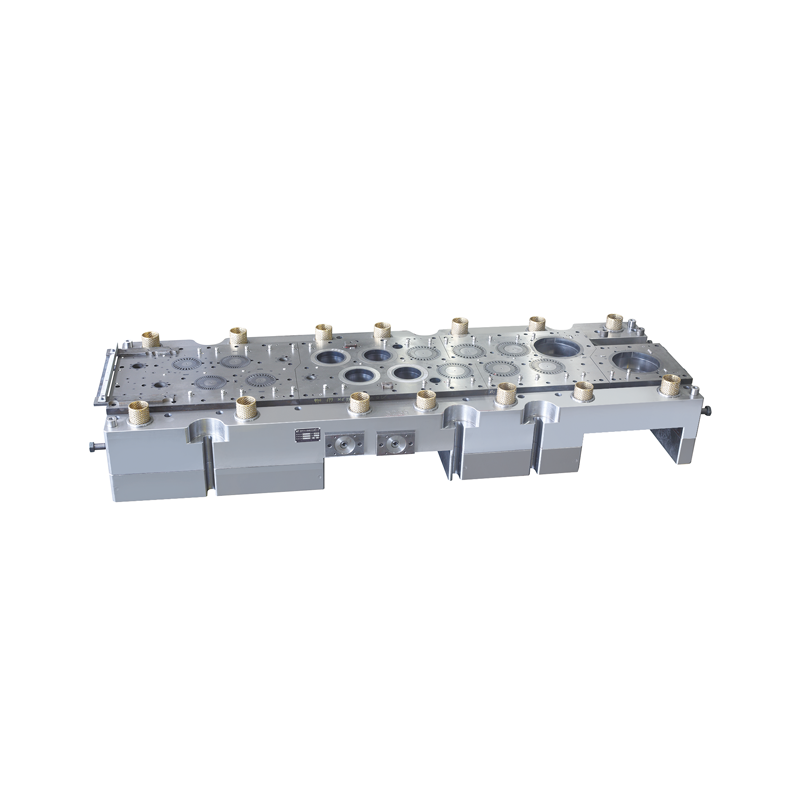

In motor core manufacturing, efficiency and precision are closely connected. A reliable Precision Stamping Mold helps streamline production, reduce material waste, and maintain consistent output. Our 155 Double-row Precision Progressive Metal Stamping Die, for instance, features a three-slot design for the stator and a two-slot design for the rotor. This setup allows multiple products to be produced without changing molds, which enhances mold utilization and reduces development costs.

A Precision Stamping Mold experiences wear over time, but careful design choices can extend its service life. High-hardness blade materials, precision guide parts, and a robust three-plate mold base contribute to durability. Blade dies achieve life cycles over 5 million strokes per 0.1mm, while proper control of blanking speed—from 80 to 280 punches per minute—reduces stress on the die. Monitoring concentricity, riveting force, and protection devices ensures uniformity and reduces maintenance frequency.

Motor cores often require features like self-locking slots, skewed slots, or step-hole punching. A Precision Stamping Mold Company capable of customization can accommodate laminations ranging from Φ12 to Φ720mm, producing single-row, double-row, or multi-row layouts. Progressive dies with multiple slots allow simultaneous processing of stators and rotors, saving time and simplifying production planning. Flexible molds also allow straight stacking with internal riveting, skew slot internal riveting, or large rotary internal riveting, depending on design specifications.

Choosing a Precision Stamping Mold involves more than size considerations. Effective cutting-edge height, guide accuracy, blade quality, and misfeed protection all affect production quality. Molds that allow interchangeable plates reduce downtime for varying rotor diameters, while features like conveyor output, rotor control, and chute devices support continuous high-speed operation. A company offering detailed support and replacement parts—commonly supplying 30% of wearing components—helps maintain consistent output.

Modern Precision Stamping Mold designs reduce burrs, maintain concentricity within 0.05mm, and optimize production flow. Special polishing processes remove oxidation from punches, extending life and improving performance. High-speed progressive stamping molds can reach 280 punches per minute during running-in periods, maintaining precision without sacrificing speed. By combining great design with adaptable mold structures, the Precision Stamping Mold Company provides solutions tailored to evolving motor core requirements.

Investing in a Precision Stamping Mold is central to achieving reliable, efficient motor core production. Factories that integrate high-precision design, flexible customization, and durable materials can handle complex laminations efficiently. Partnering with a Precision Stamping Mold Company ensures access to great dies, tailored solutions, and consistent output across various applications.

A well-designed Precision Stamping Mold is a crucial element for consistent motor core production. By combining durable materials, precise guide systems, and flexible customization, manufacturers can process a wide range of rotor and stator laminations efficiently. Working with a skilled Precision Stamping Mold Company provides access to tailored solutions, interchangeable mold plates, and great protection features, helping maintain accuracy, reduce downtime, and support evolving production needs. Proper mold selection and ongoing maintenance contribute to long-term performance and reliable output across various applications.