2025.11.14

2025.11.14

Industry News

Industry News

Precision is the silent promise behind every well-made metal part. From motor stators to micro components, consistency depends on one key element - the Precision Stamping Mold. Behind these molds are the experts who build them: the engineers and technicians of a Precision Stamping Mold Company. Their job goes far beyond cutting and pressing metal.

Every production line that works like clockwork has one thing in common - a stable and durable Precision Stamping Mold. The mold defines how materials move, bend, and take shape. It decides how clean each cut will be, how tightly each tolerance is held, and how fast the process can run without failure.

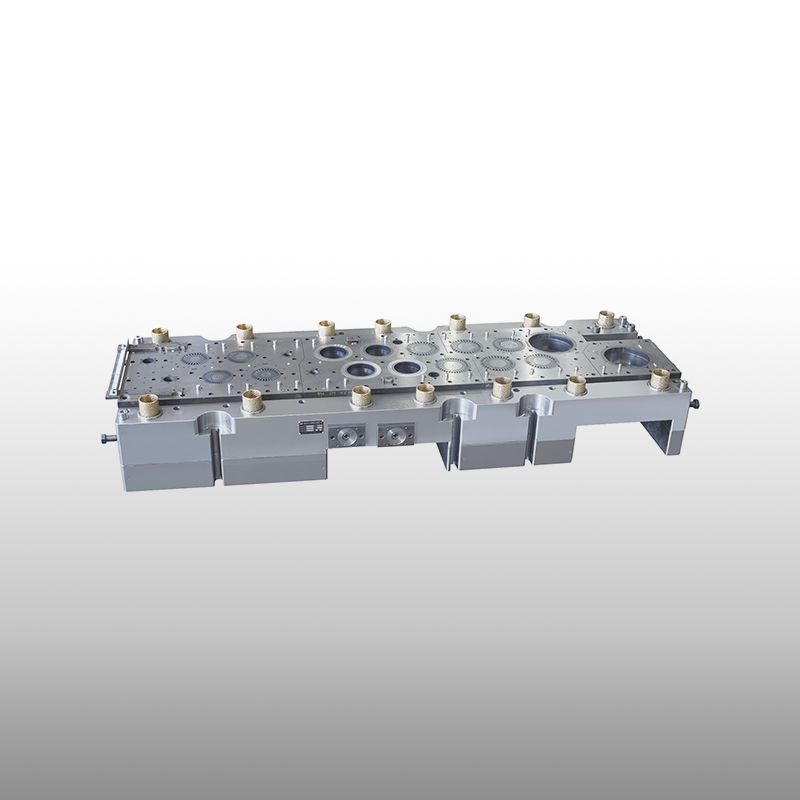

A professional Precision Stamping Mold Company focuses on the details that many people never see. For example, a mold designed with a three-plate base and ball guide improves alignment during high-speed runs. When the effective cutting edge reaches about 8mm and the concentricity stays within 0.05mm, every stroke contributes to a cleaner result and a longer mold life. Precision like this isn't achieved by chance; it's the product of experience and control over every step of production.

Every factory faces different production goals - some prioritize speed, others focus on flexibility. That's where the strength of a Precision Stamping Mold Company really shows. Customization allows one mold to serve multiple purposes, reducing costs and saving time in development.

Take, for instance, a double-row progressive mold designed for both stator and rotor production. Its structure allows multiple products to be made without switching molds. This not only increases utilization but also gives manufacturers the freedom to adapt quickly to changing product lines.

The right customization isn't about fancy technology; it's about practical engineering that matches the user's workflow.

It's easy to talk about speed in numbers - 280 punches per minute sounds impressive. But in the real world, speed without consistency creates problems. A dependable Precision Stamping Mold Company understands how to balance these elements.

During the running-in period, a stable punching speed and burr control (often less than 0.05mm) help the mold maintain its rhythm. Protection devices like misfeed detection or equal-height limit columns keep the line steady and safe from costly interruptions. Meanwhile, guide components with high hardness levels keep every movement aligned, even after millions of cycles.

When production can continue for 160 million punches or more, factories gain not just productivity but also peace of mind. The mold becomes more than a tool - it becomes part of the production identity.

Precision isn't a one-time achievement. A reliable Precision Stamping Mold Company understands that performance must be sustained over time. That's why technical support and spare parts supply are part of the package.

Providing around 30% of wearing components and offering guidance on maintenance keeps the mold's performance stable. These measures protect production lines from unnecessary downtime. In industries where every second counts, that support can make a real difference.

From the initial design discussion to the final assembly on the factory floor, these companies act as partners, not just suppliers. Their focus on feedback, data, and continual improvement helps clients maintain efficiency long after delivery.

A dependable Precision Stamping Mold Company doesn't just make tools; it builds the foundation for reliability. In a world where production never stops, the quiet strength of precision keeps everything moving forward - one stroke at a time.