2025.11.21

2025.11.21

Industry News

Industry News

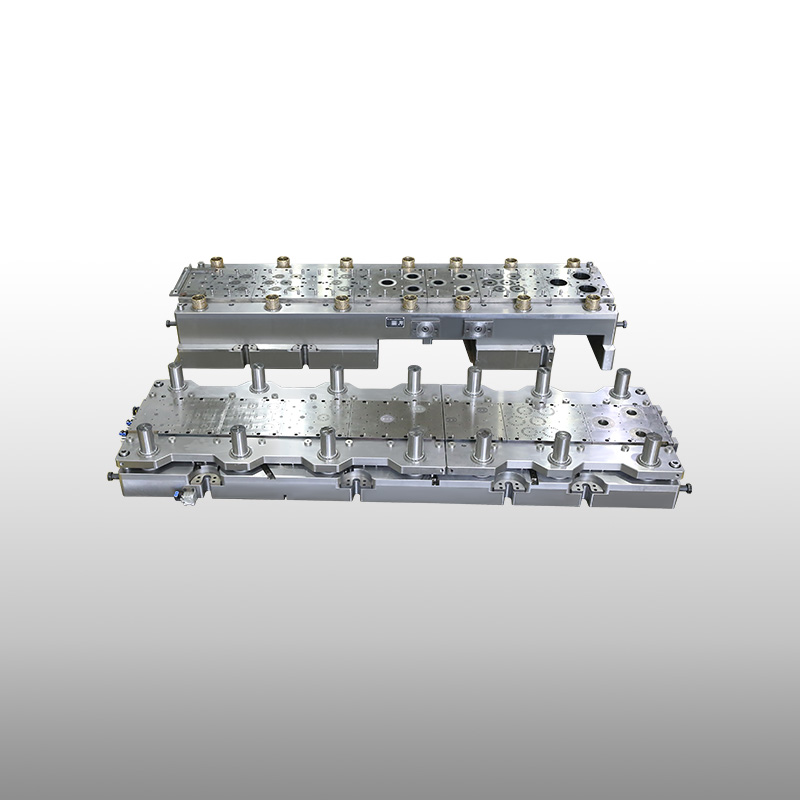

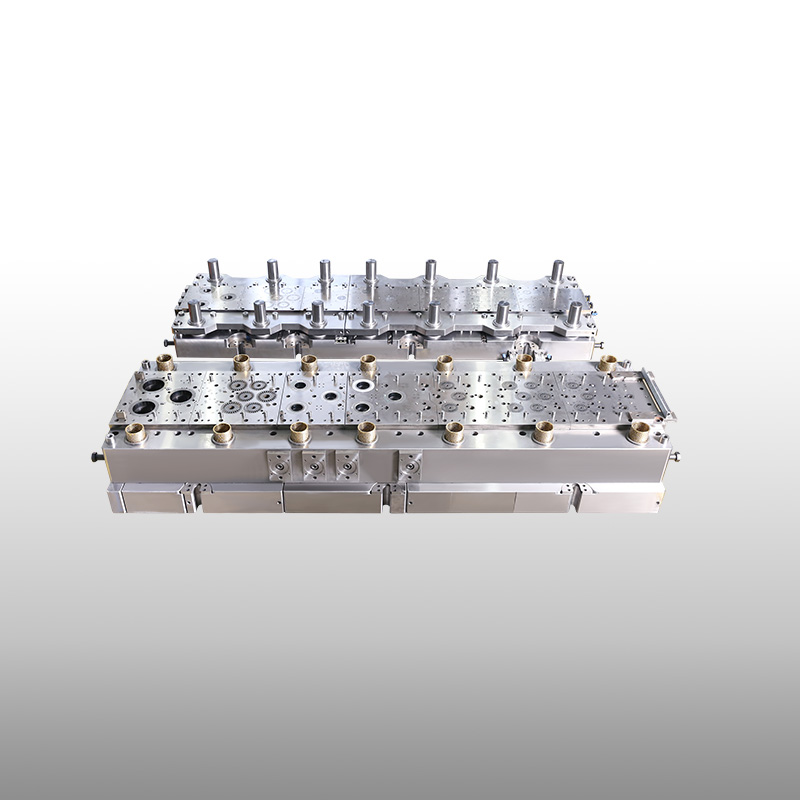

In modern manufacturing, precision and adaptability have become key factors in staying competitive. A reliable Mold Customization Manufacturer helps bridge the gap between design and production, allowing factories to create components that match exact specifications while maintaining consistency and efficiency. Mold customization has evolved from a specialized service into a strategic solution that drives better outcomes across diverse industries.

The core advantage of Mold Customization lies in precision. Every mold is designed according to the unique structure, material, and dimensional needs of the final product. Whether it's for metal parts, electronic housings, or automotive components, customized molds make it possible to achieve uniform shapes and detailed finishes. This precision not only reduces material waste but also cuts down on post-processing time, which directly improves overall production efficiency.

When molds are tailored to fit your production line, operators spend less time adjusting machinery or correcting defects. Instead, production becomes smoother, and products maintain consistent quality from start to finish.

A professional Mold Customization Manufacturer understands that no two projects are alike. That's why customization services extend beyond just shaping materials-they cover every aspect of production, from selecting suitable metals or composites to optimizing cooling systems, runner designs, and surface treatments.

It also supports the transition from prototyping to mass production without losing precision or performance stability. For companies exploring new product lines, mold customization becomes a critical advantage in responding to market demands with speed and reliability.

Modern Mold Customization services rely heavily on great engineering tools. Computer-aided design (CAD), CNC machining, and 3D scanning technologies make it possible to simulate and refine every aspect of the mold before actual production. This digital integration minimizes potential errors and shortens the time needed for adjustments.

Real-time quality inspection and data tracking systems help manufacturers monitor mold wear, performance, and production cycles. By working with a mold customization manufacturer that embraces these technologies, businesses gain better control over production quality while maintaining cost efficiency.

Investing in customized molds is not just about getting a one-time tool-it's about building a long-term production foundation. High-quality molds crafted from durable materials like steel, aluminum, or specialty alloys can endure demanding operating environments while maintaining dimensional accuracy.

A skilled Mold Customization Manufacturer designs molds for longevity, meaning fewer replacements, less downtime, and more consistent output. Over time, this stability directly contributes to improved profitability and customer satisfaction, especially in high-volume manufacturing sectors where precision and reliability are critical.

Partnering with a trusted mold customization manufacturer offers more than just a product-it delivers a process improvement strategy tailored to your goals. From small-batch prototypes to large-scale production runs, Mold Customization empowers factories to operate with precision, efficiency, and adaptability in a rapidly changing market.

By understanding each client's specific challenges and applying the right combination of engineering experience and technology, a professional mold customization manufacturer helps turn production goals into measurable results.