2026.02.20

2026.02.20

Industry News

Industry News

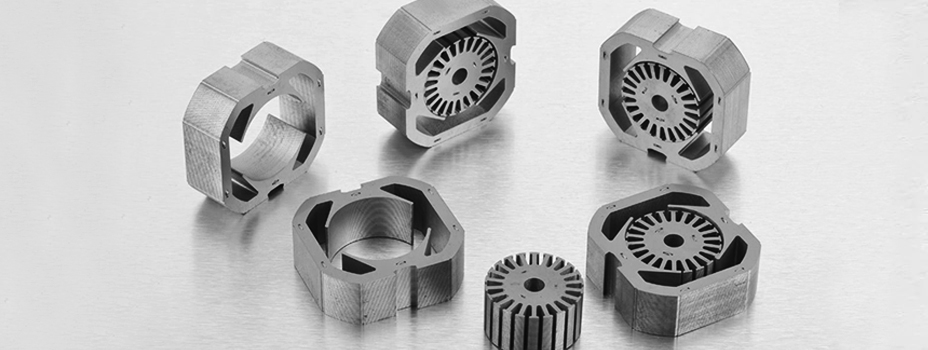

In modern manufacturing, precision molds are essential for producing consistent and reliable motor components. A Motor Core Mold can significantly improve efficiency while reducing material waste, making it an indispensable tool for industries ranging from automotive to electronics. Partnering with a trusted Motor Core Mold Manufacturer ensures access to customized solutions designed for specific production needs.

Motor cores are critical components in electric motors, and their manufacturing requires precise shaping to maintain performance. A well-designed Motor Core Mold ensures that each part meets dimensional requirements and maintains electromagnetic efficiency. Manufacturers often rely on customized molds to adapt to varying motor sizes, materials, and production volumes.

Industries face challenges like uneven lamination stacking, excessive material loss, and inconsistent core density. Custom Motor Core Mold designs address these issues by controlling material flow and alignment during production. This reduces scrap and improves overall assembly efficiency.

The choice of material in a Motor Core Mold directly impacts durability and product quality. Metal alloys with high wear resistance, such as stainless steel, are commonly used to withstand repeated cycles without deformation. A Motor Core Mold Manufacturer can provide guidance on selecting materials suitable for high-volume production or specialized prototypes.

Additionally, thermal properties of the mold material influence cooling rates, which affect core density and magnetic properties. great manufacturers incorporate design features to manage heat distribution effectively, ensuring consistent motor performance.

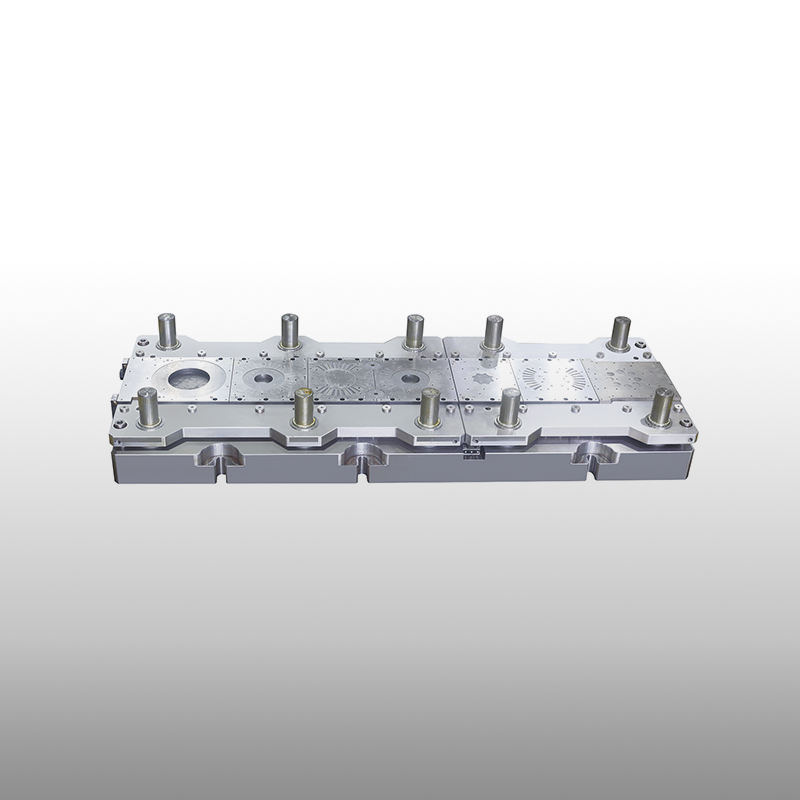

Every production line has unique requirements, making customization essential. Experienced Motor Core Mold Manufacturers offer solutions such as adjustable cavity designs, modular inserts, and surface treatments to extend mold life. These features allow manufacturers to optimize their processes without significant downtime or equipment changes.

Customization also addresses specific tolerances and dimensional constraints. Precision in mold design ensures that motor cores fit great into assemblies, reducing post-processing and assembly issues. For companies scaling production, this can translate into noticeable efficiency gains.

A well-engineered Motor Core Mold reduces common production challenges. Misalignment, uneven material distribution, and surface defects can compromise motor performance. By leveraging great mold design techniques, manufacturers can minimize these problems. Using a professional Motor Core Mold Manufacturer ensures that molds are tested for repeatability, durability, and consistency.

Proper mold design also shortens cycle times, enabling faster throughput without sacrificing quality. For large production runs, even minor efficiency improvements can have a significant cost impact.

Selecting a manufacturer goes beyond price. Look for experience in motor core applications, strong technical support, and the ability to offer tailored mold solutions. Collaboration with a knowledgeable Motor Core Mold Manufacturer ensures that your specific production challenges are understood and addressed.

Consider the manufacturer's ability to support both prototyping and full-scale production. Flexibility in design, material choice, and post-delivery support is critical for maintaining long-term operational efficiency.

Investing in a reliable Motor Core Mold from a trusted Motor Core Mold Manufacturer helps streamline production, improve product quality, and reduce waste. By focusing on material selection, precise design, and customization options, manufacturers can solve key challenges in motor core production and maintain consistent performance across all runs.