2026.02.13

2026.02.13

Industry News

Industry News

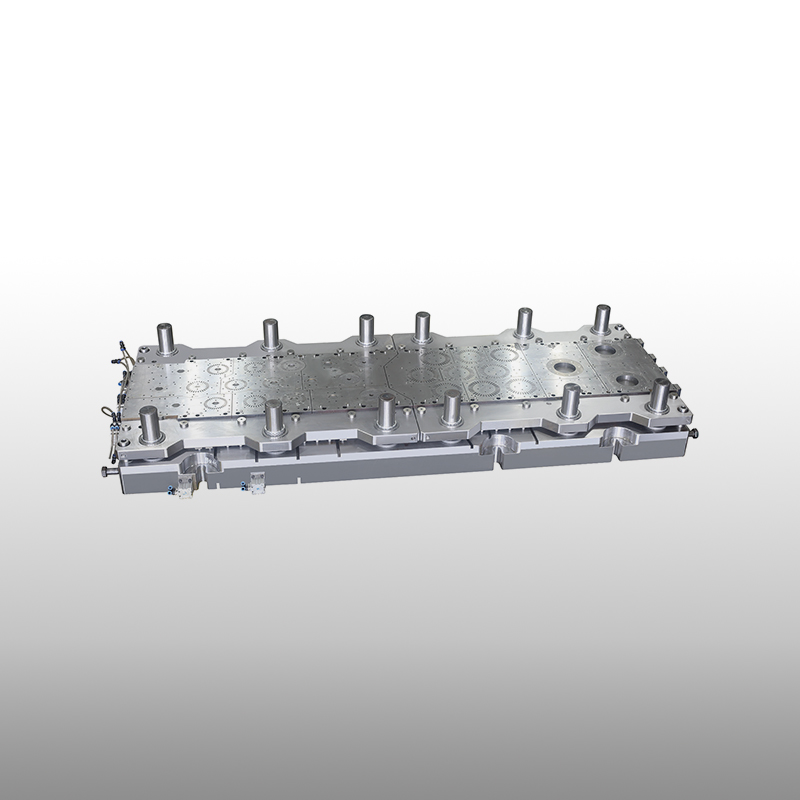

A stamping mold is a core tool used to shape metal sheets into defined parts through controlled force and repeatable motion. In manufacturing environments, it supports stable output while keeping dimensions aligned with drawings. Many factories depend on this tooling to handle medium to high-volume production where consistency matters more than speed alone.

Unlike generic tooling, a stamping mold is designed around the part itself. Thickness, edge detail, forming depth, and material behavior all influence how the mold is built. This is why early design communication plays a strong role in downstream production stability.

Dimensional variation is a common concern in metal forming. A stamping mold directly controls how force is distributed across the material, which affects springback, edge definition, and flatness. Tool geometry, clearance, and surface treatment all contribute to how predictable each stroke becomes.

Factories with in-house engineering often adjust mold structures to match material grades and press conditions. This approach reduces rework and avoids unnecessary secondary processing.

Mold customization allows manufacturers to adapt tooling to specific machines, materials, and output targets. Instead of forcing production to adapt to standard tooling, customized molds support smoother workflows.

Customization may involve punch layout, guide structures, wear zones, or part ejection design. For industries like automotive components or electrical hardware, this flexibility supports tighter control during continuous runs. A well-designed stamping mold can align with both prototype needs and scaled production without repeated redesign.

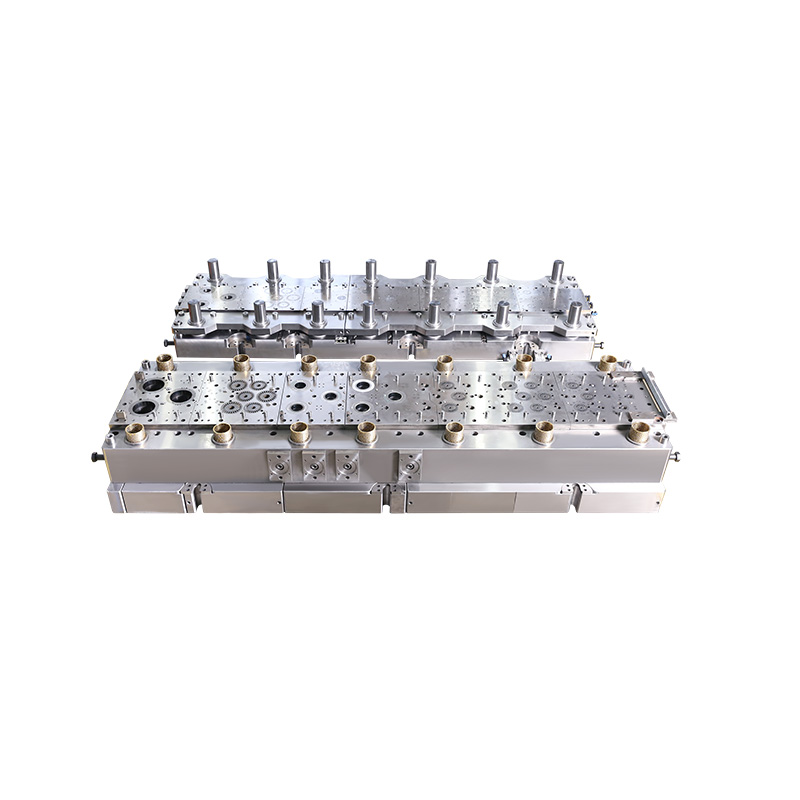

Material choice in a stamping mold affects wear behavior and maintenance cycles. Tool steels and alloy options are selected based on sheet hardness, stroke frequency, and expected output volume. Heat treatment and surface finishing also play roles in keeping edges stable over time.

Rather than focusing only on hardness, experienced teams balance toughness and machinability. This allows the mold to maintain working accuracy while remaining serviceable during long-term use.

A stamping mold manufacturer is more than a tool supplier. They often act as a technical partner during part development. Clear communication around drawings, tolerances, and press conditions helps avoid mismatches later.

Sharing information such as material grade, annual volume, and part application allows the manufacturer to adjust internal structures accordingly. This collaboration supports smoother sampling and fewer adjustments after approval.

Small design choices can influence daily production more than expected. Guide alignment affects repeatability. Stripper design impacts surface marks. Ejection methods influence cycle rhythm.

A stamping mold manufacturer with production experience typically designs around real press behavior rather than ideal lab conditions. This results in tooling that runs steadily instead of requiring constant operator attention.

All tooling experiences wear. A stamping mold designed with maintenance in mind can be serviced without full disassembly. Replaceable inserts and accessible wear areas reduce downtime and simplify upkeep.

Factories often schedule inspection cycles based on stroke counts rather than calendar time. This approach aligns maintenance with actual usage instead of assumptions.