2026.02.06

2026.02.06

Industry News

Industry News

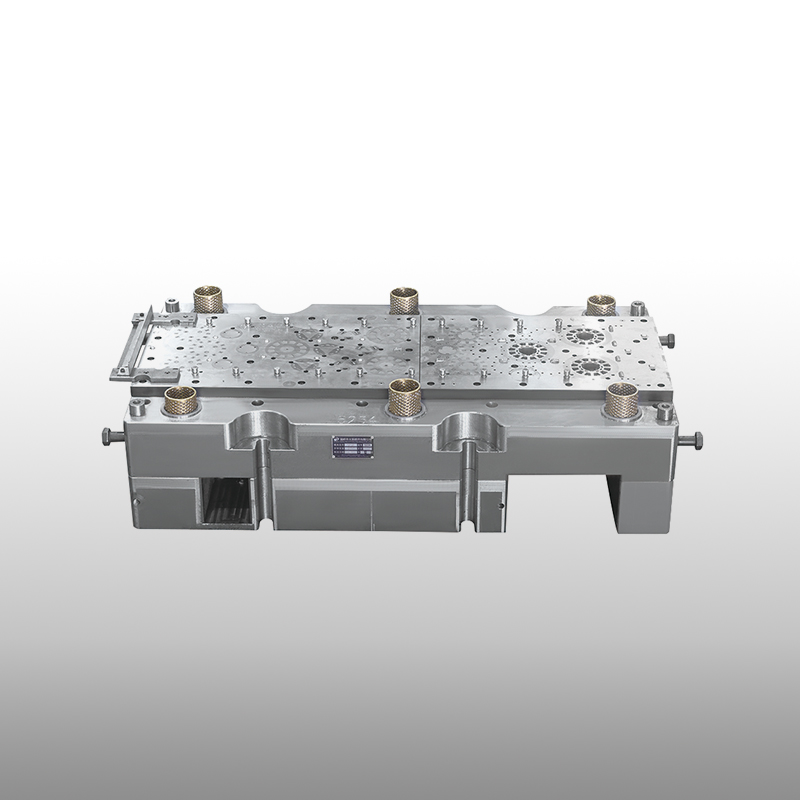

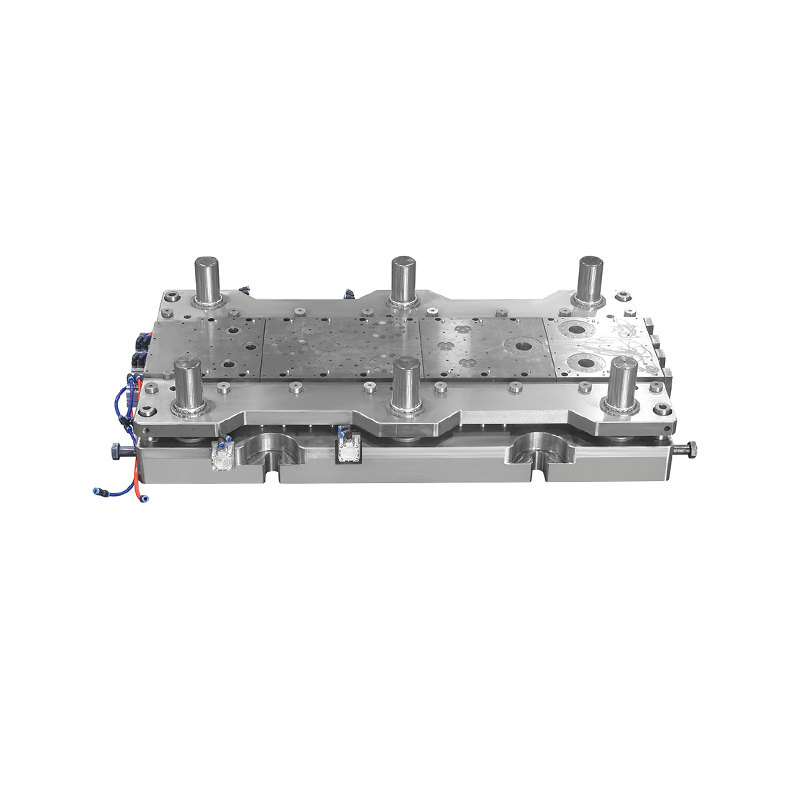

Stamping Die Design plays a central role in shaping metal components that are used across many industrial products. A well-developed die layout determines how material flows, how pressure is distributed, and how consistently parts are formed during production. For factories handling custom metal components, die structure directly affects efficiency, tool lifespan, and part uniformity.

From an engineering perspective, Stamping Die Design is not just about shaping metal. It reflects how a product will behave across repeated cycles. When dies are planned carefully, manufacturers experience smoother workflows and fewer interruptions on the shop floor.

Mold customization focuses on tailoring tools to specific production requirements. In stamping operations, customization allows each die to match part geometry, material thickness, and output volume. This approach supports flexible production planning without relying on generic tooling.

A Stamping Die Design Manufacturer often works closely with engineering teams to adjust die structures for different use cases. These adjustments may involve punch layout, guiding systems, or material selection. Customization allows factories to respond to changes in product design without rebuilding the entire tool set.

Material choice influences how long a die remains stable during repeated stamping cycles. Tool steels and alloy options are selected based on wear resistance and structural stability. The selected material also affects maintenance schedules and reworking frequency.

During Stamping Die Design development, material decisions are aligned with production rhythm and part complexity. Thicker sheets and harder metals require stronger die structures. Matching the die material to application conditions supports steady production output over time.

Tolerance management is a key focus in Stamping Die Design. Tight tolerances demand accurate alignment and controlled deformation. When tolerance planning is overlooked, dimensional variation becomes more frequent.

A Stamping Die Design Manufacturer typically reviews part drawings and usage scenarios before locking in die dimensions. This process helps maintain dimensional consistency across batches while reducing adjustments during production runs.

Problems such as material distortion, uneven edges, or excessive tool wear often trace back to early design decisions. Poor layout or insufficient support zones can increase stress concentration within the die.

Thoughtful Stamping Die Design addresses these challenges by balancing force distribution and material flow. This approach reduces downtime associated with tool correction and extends the usable life of the die.

High-volume manufacturing places repeated stress on tooling systems. Stamping Die Design must account for cycle speed and thermal conditions caused by continuous operation. Dies are built for this environment feature reinforced structures and stable guiding components.

A Stamping Die Design Manufacturer considers production rhythm during development to support consistent output. This preparation helps factories maintain steady throughput without frequent tool intervention.

Custom metal molds are widely used alongside stamping dies in many production environments. While their forming methods differ, both rely on precision tooling and durable construction. In stamping applications, custom metal molds may support secondary shaping or alignment processes.

Integrating custom metal molds with Stamping Die Design allows manufacturers to streamline workflows. Coordinated tooling reduces handling steps and supports consistent part geometry throughout production.